DVME được thành lập bởi các thành viên có hơn mười năm kinh nghiệm làm việc và cung cấp vật tư, thiết bị cho nhiều công ty, tập đoàn tại Việt Nam. Chúng tôi hướng tới việc cung cấp các giải pháp và tư vấn chuyên nghiệp cho khách hàng đồng thời cũng là cầu nối, đại diện cho các nhà sản xuất muốn mở rộng kinh doanh tại thị trường Việt Nam.

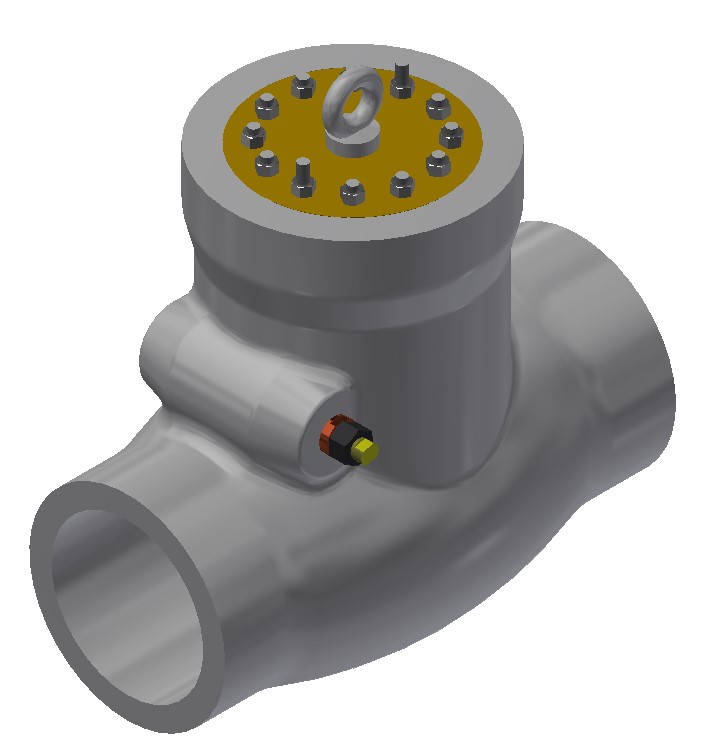

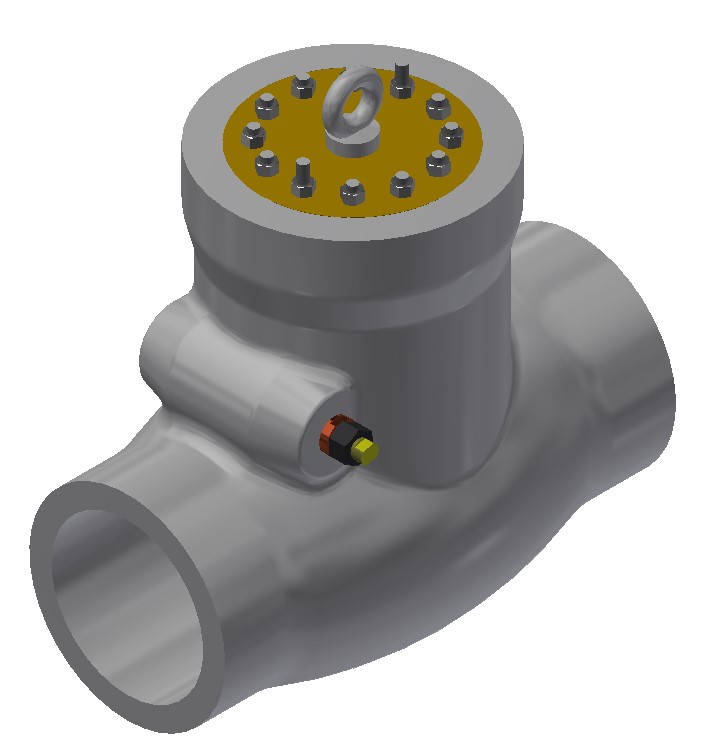

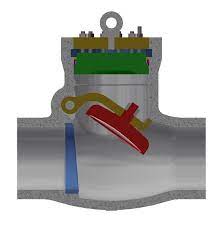

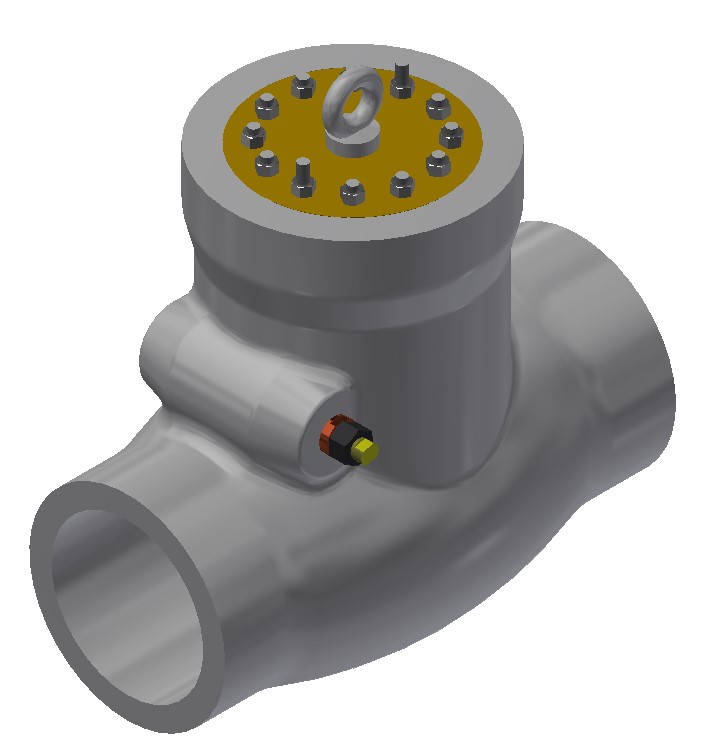

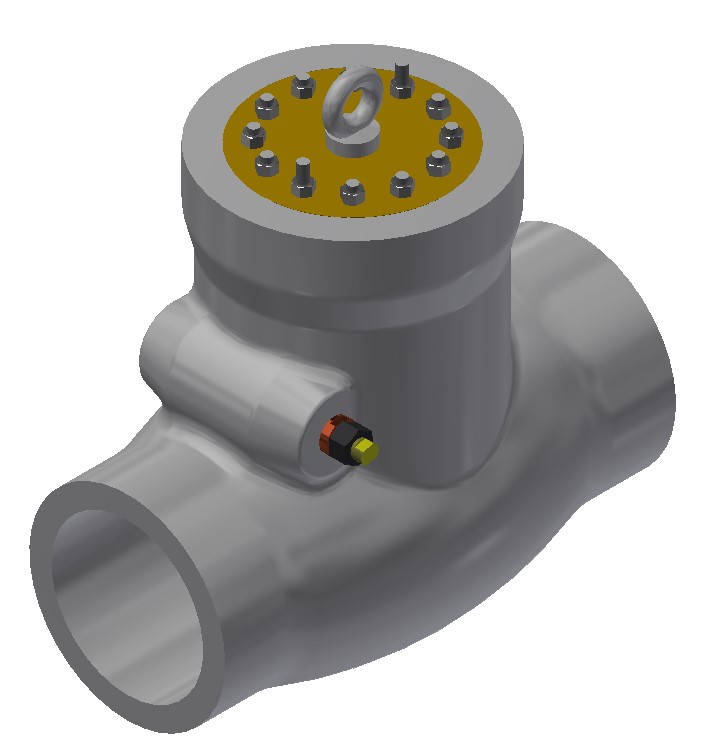

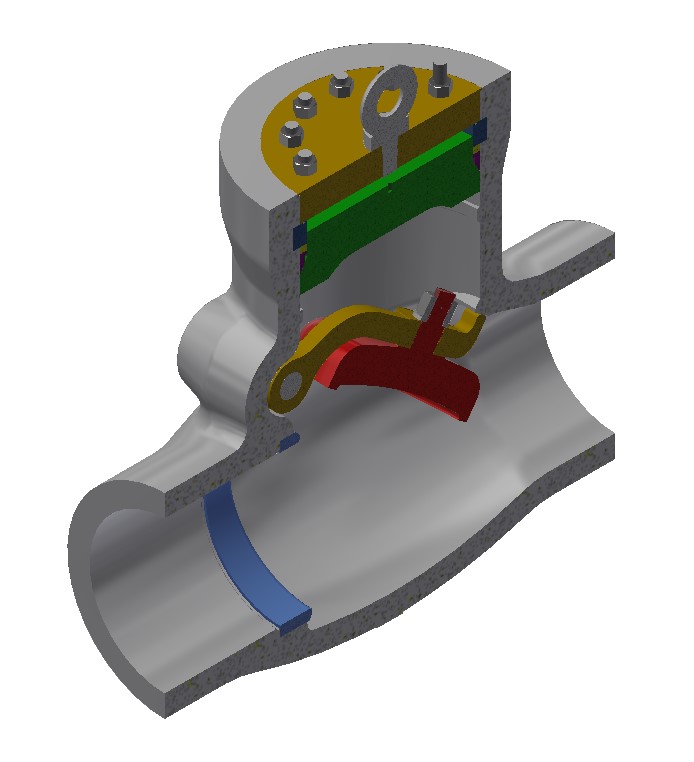

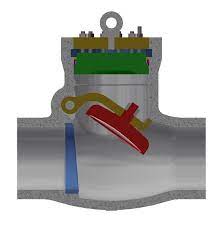

Pressure seal Swing Check valve

Liên hệ

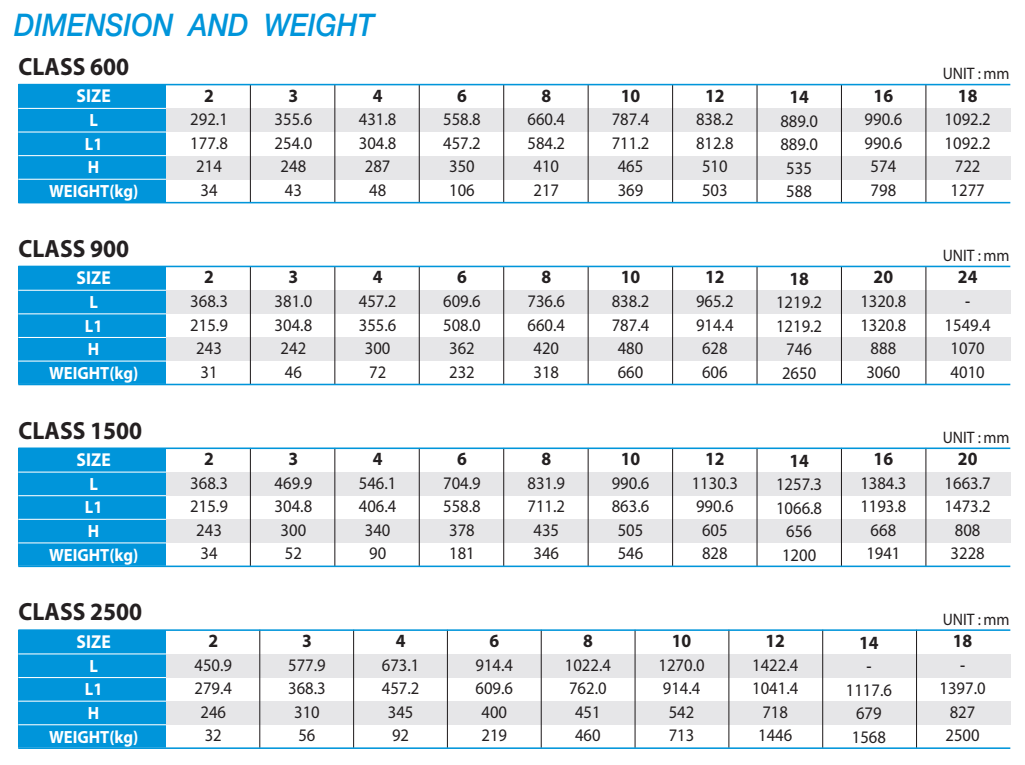

- Size: from 2″ to 42″

- Class: 600# to 4500#

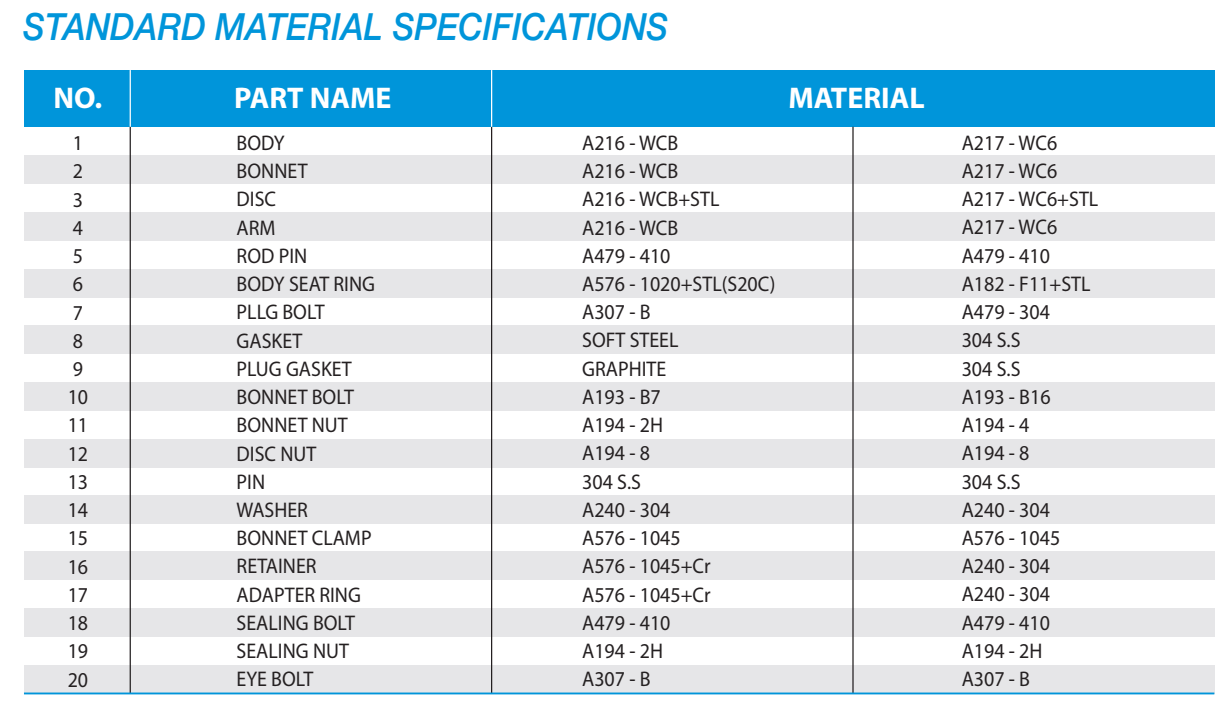

- Material: ASTM A216-WCB or Equivalent, ASTM A217-WC6, WC9, C5, C12, C12A; ASTM A351-CF8, CF8M, CF3, CF3M, CN7M; ASTM A995-1A, 2A, 4A, 5A; Inconel 625, Incoloy 825, Hastelloy C, Monel, AL-BRONZE; ASME SA designation material(e.g ASME SA217-WC6).

Mô tả

DESIGN

Pressure seal valves are intended for high-pressure and high-temperature applications in all types of fluid, except where severe coking may occur.

A selection of designs and materials would give an excellent service in nuclear steam generating stations, industrial/chemical plants, and thermal power plants.

The pressure seal valve provides the most efficient use for flow passage and sealing, and results in significant weight saving and ease and simple installation and maintenance. Manufacturing and quality assurance procedures include extra controls of dimensional and non-destructive examinations and tests on critical areas such as gasket sealing, weld ends, or stelite sealing surfaces.

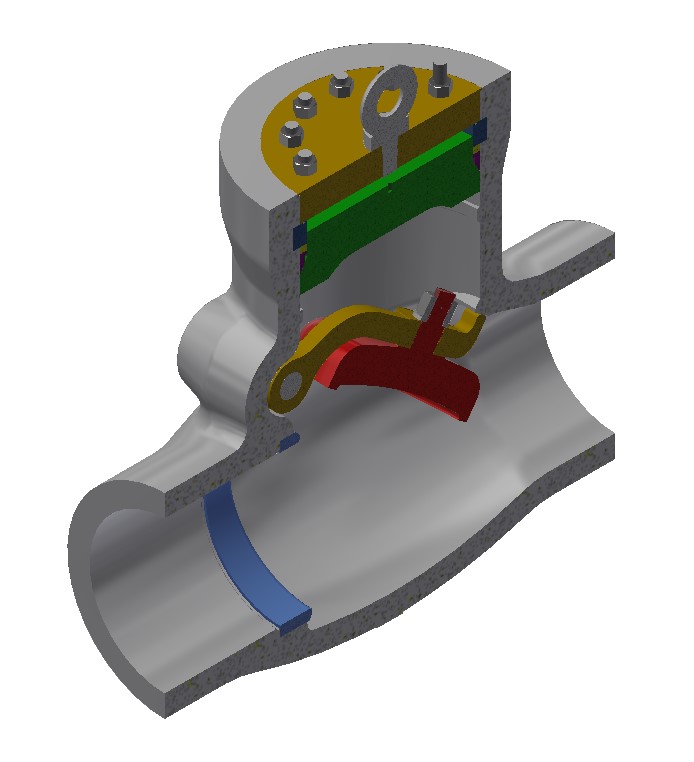

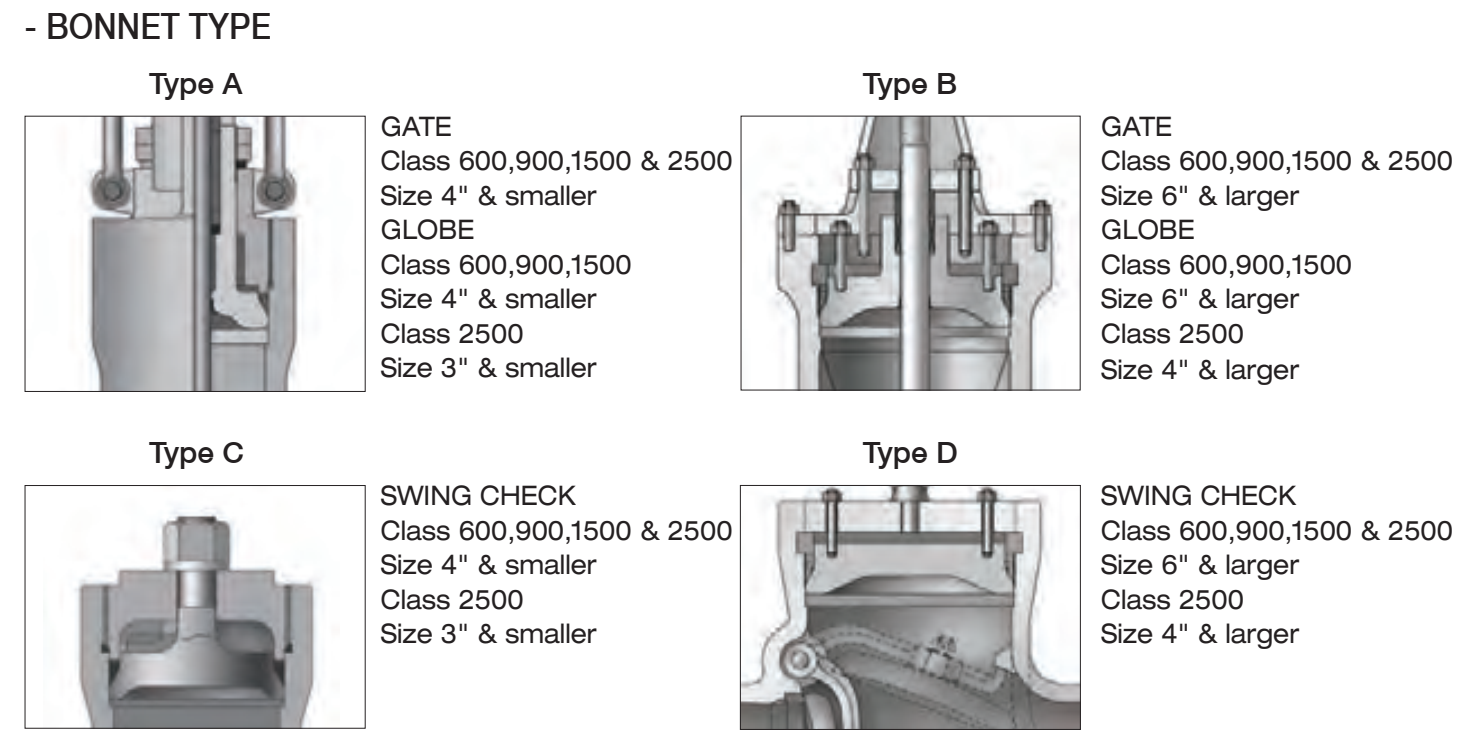

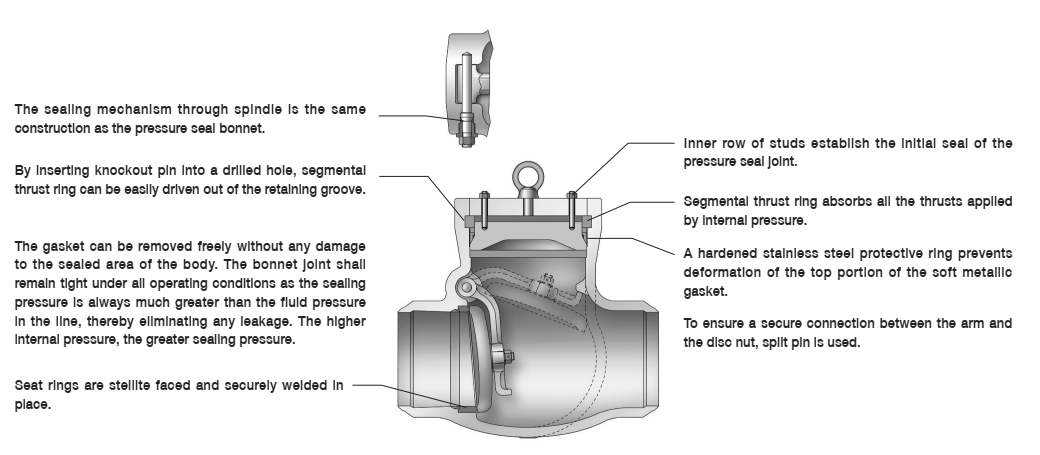

CONSTRUCTION

- BODY AND BONNET

- BODY: Flow areas are designed for minimum turbulence and pressure drop.

- BONNET: Ample stuffing box and stellite back seat are to guide accurately stem and back seat.

When designing a PK valve, casting of body and bonnet shall be considered thoroughly as a quality requirement.

SERVICE RECOMMENDATION

- The swing check valve shall be operated in a manner to avoid the following troubles;

- Formation of excessive-high surge pressure as a result of valve closing, and

- Rapid fluctuating movement of valve closing member. The excessively high surge pressure by valve closing is prevented by closing the valve fast enough not to develop a significant reverse flow on a sudden shutoff which is a source of the surge pressure. Thus, the closing speed of valve should match closely with the speed of forward flow retard.

The rapid fluctuating movement of valve closing member must be avoided to prevent the moving valve parts from excessive wear which may result in early failure of valve.

Such movements can be precluded by sizing the valve to a flow rate which forces the closure member not to move.

- The swing check valve can also be mounted to the vertical position, provided the disc should not reach the valve position. However, the closing moment of disc by weight is very low in fully-opened position, so the valve tends to close late.

In order to overcome such slow response to flow retardation, the disc may be supplied with a lever-mounted weight or with spring loaded.

DESIGN DATA FEATURES

- Comply with the following standards; ASME B16.25, B16.34, MSS-SP-25, API 600 Style A.

- The butt-welded end details of PK standard product shall be prepared in accordance with ASME B16.25

Đánh giá

Chưa có đánh giá nào.