DVME được thành lập bởi các thành viên có hơn mười năm kinh nghiệm làm việc và cung cấp vật tư, thiết bị cho nhiều công ty, tập đoàn tại Việt Nam. Chúng tôi hướng tới việc cung cấp các giải pháp và tư vấn chuyên nghiệp cho khách hàng đồng thời cũng là cầu nối, đại diện cho các nhà sản xuất muốn mở rộng kinh doanh tại thị trường Việt Nam.

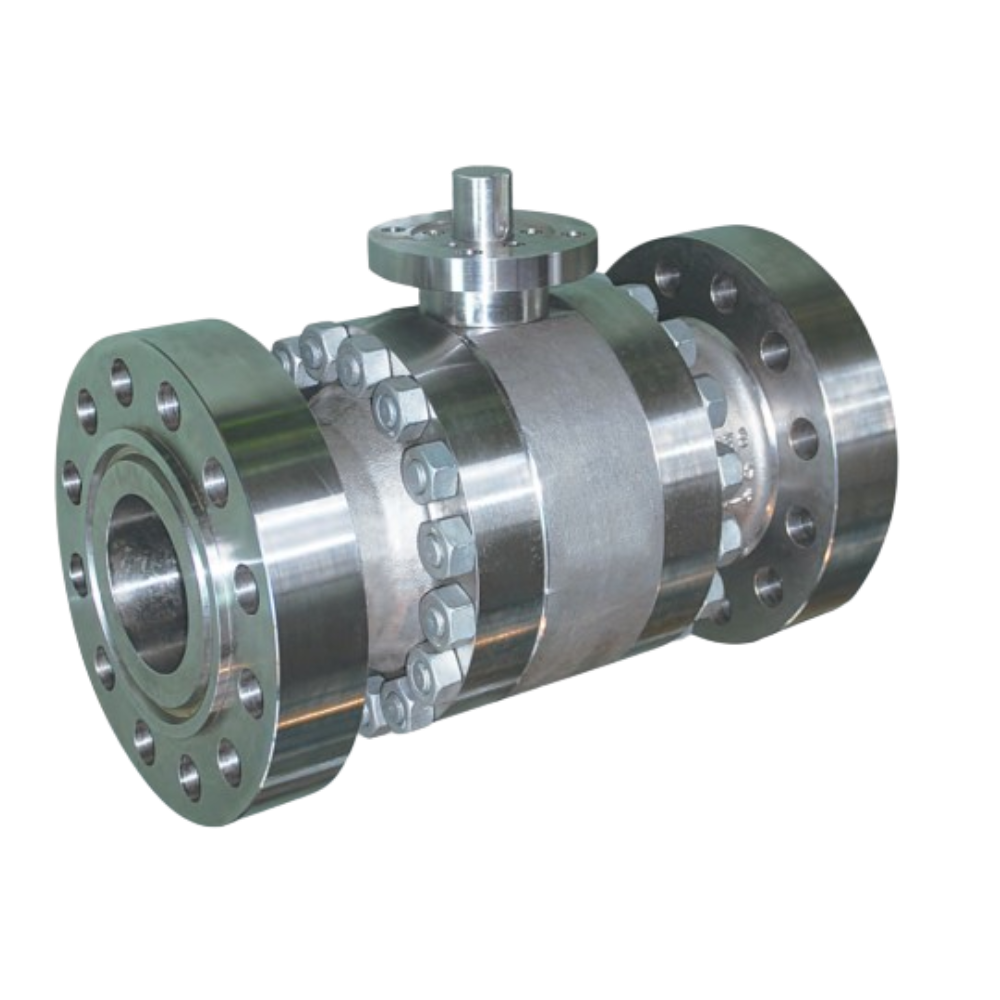

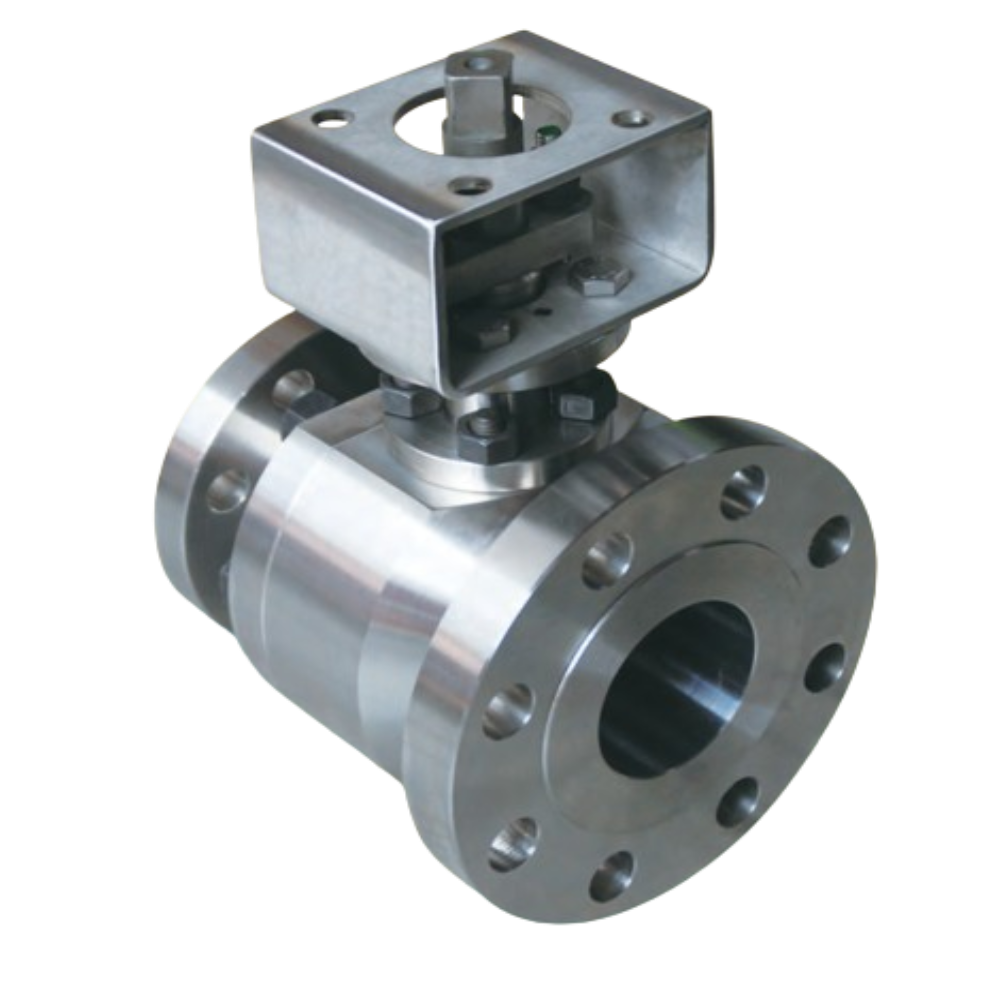

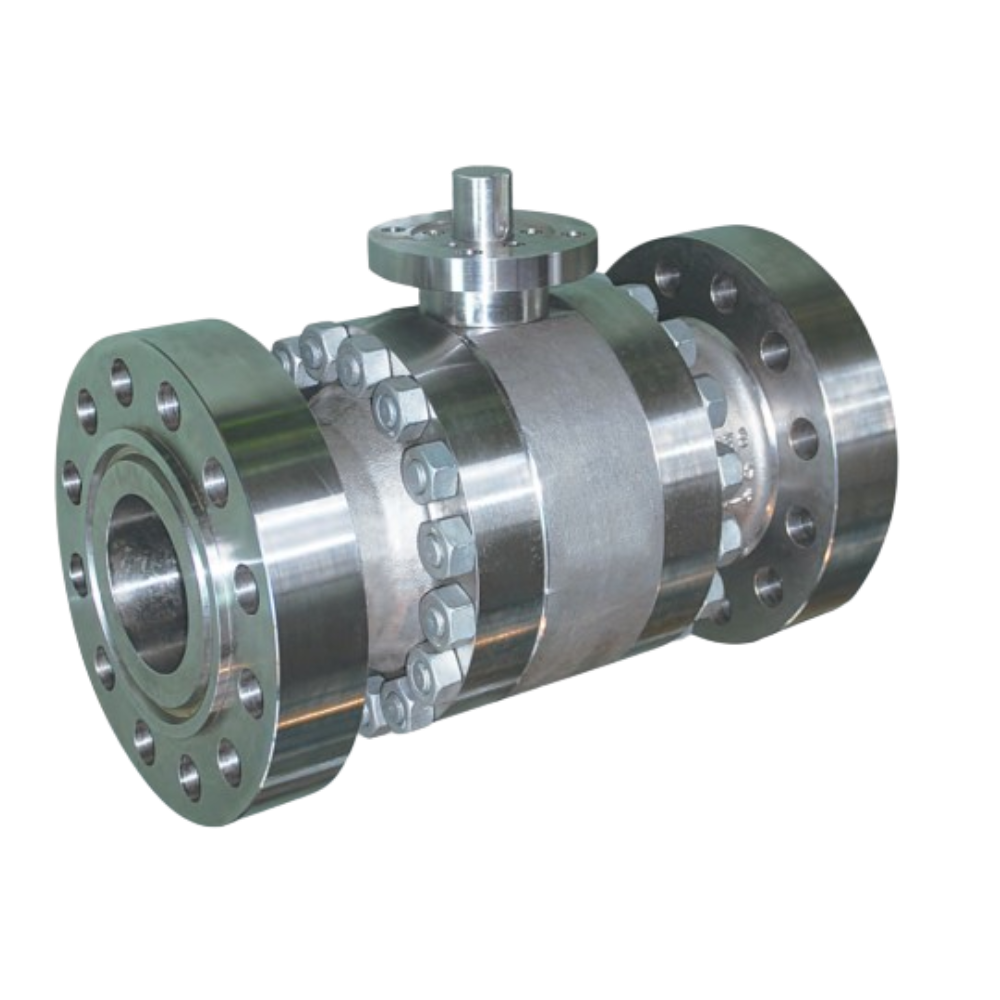

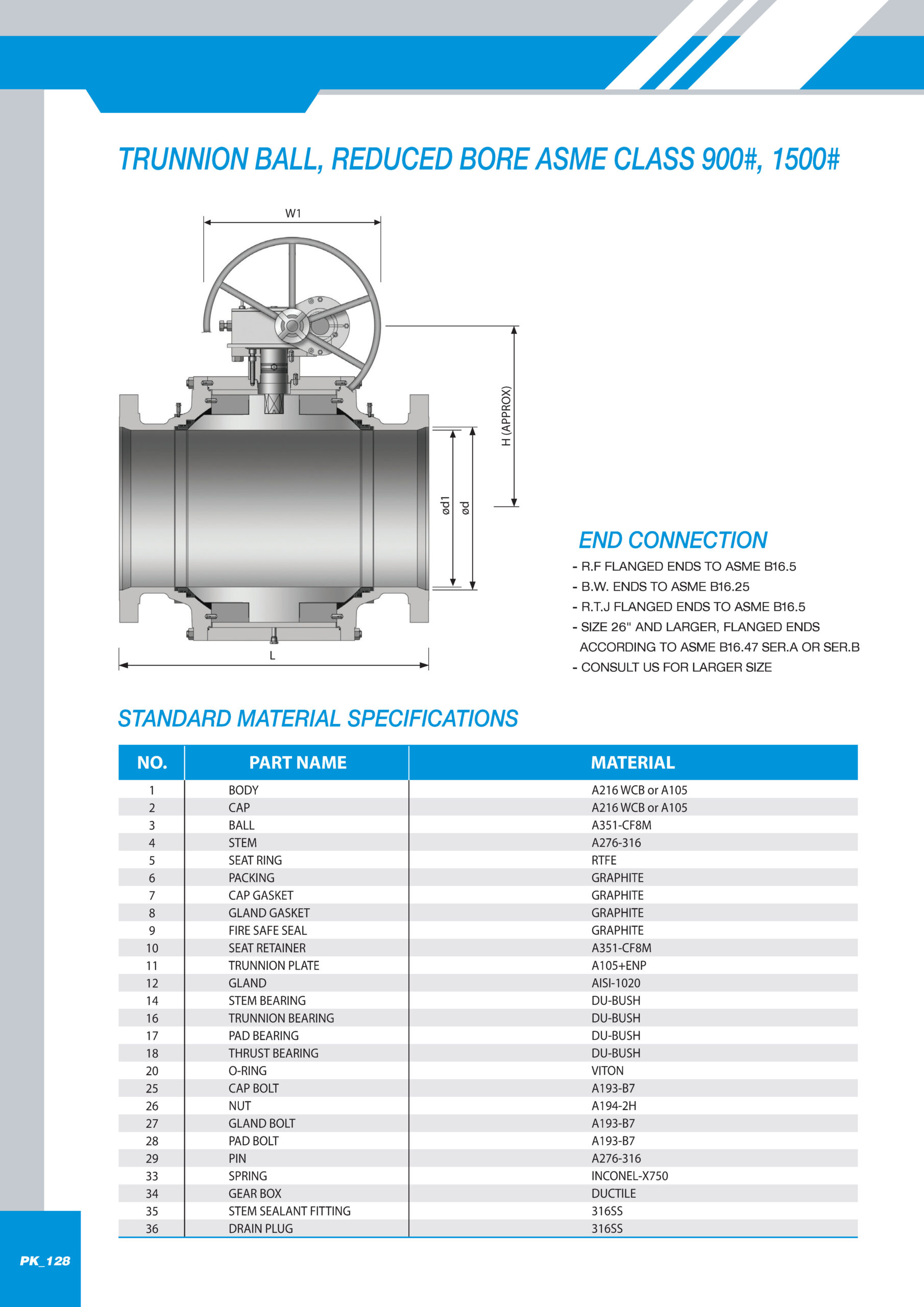

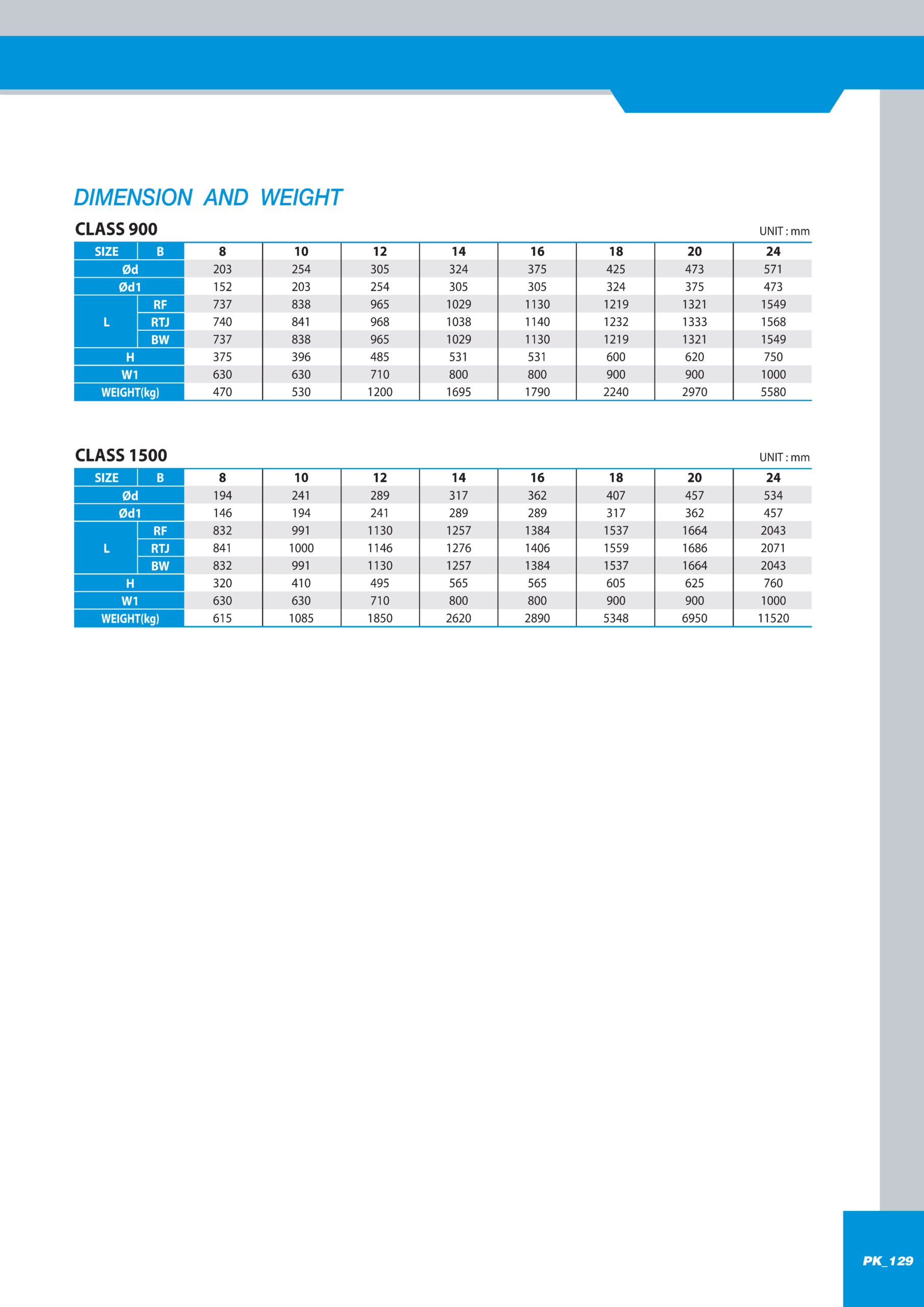

Ball valve

Liên hệ

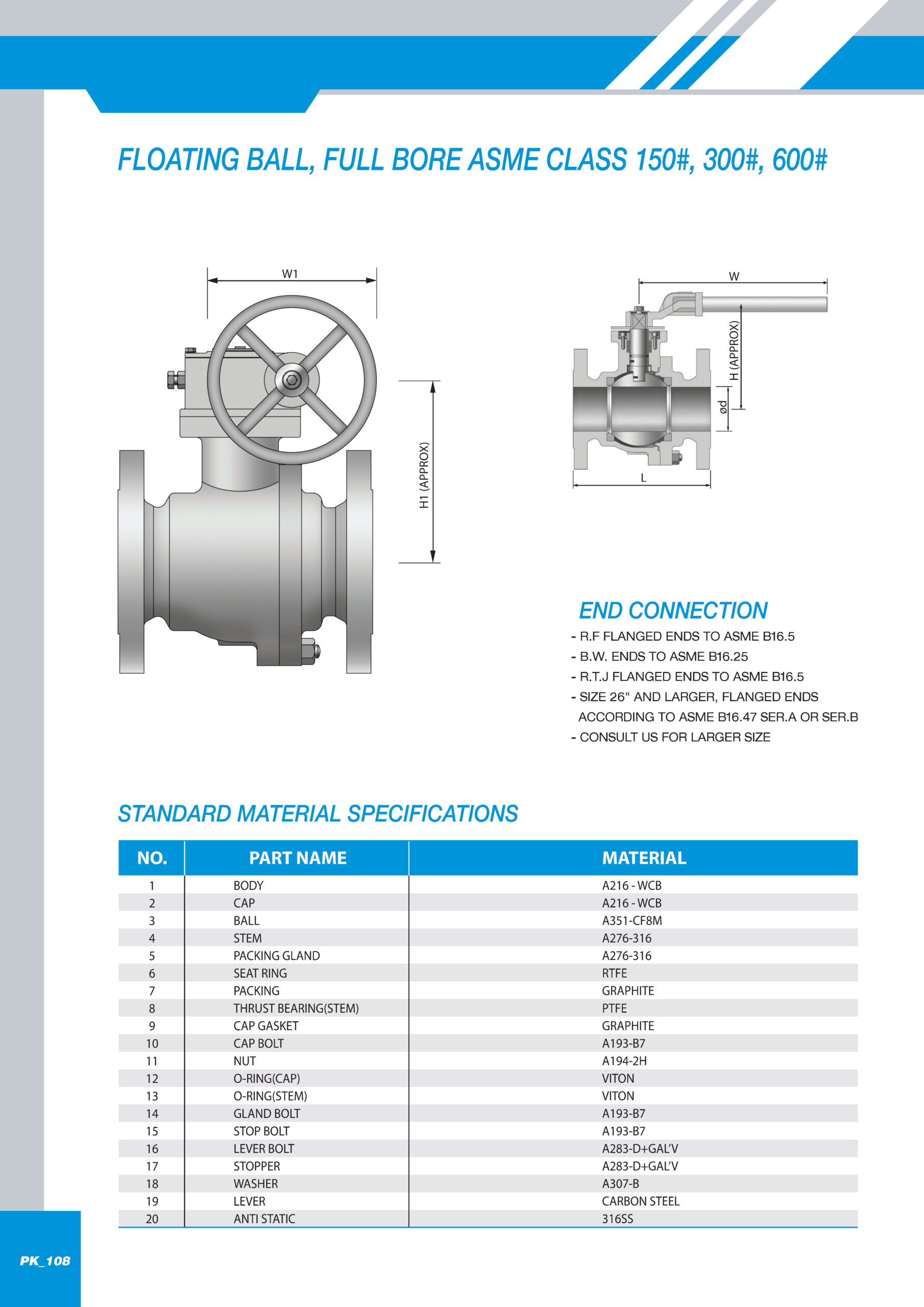

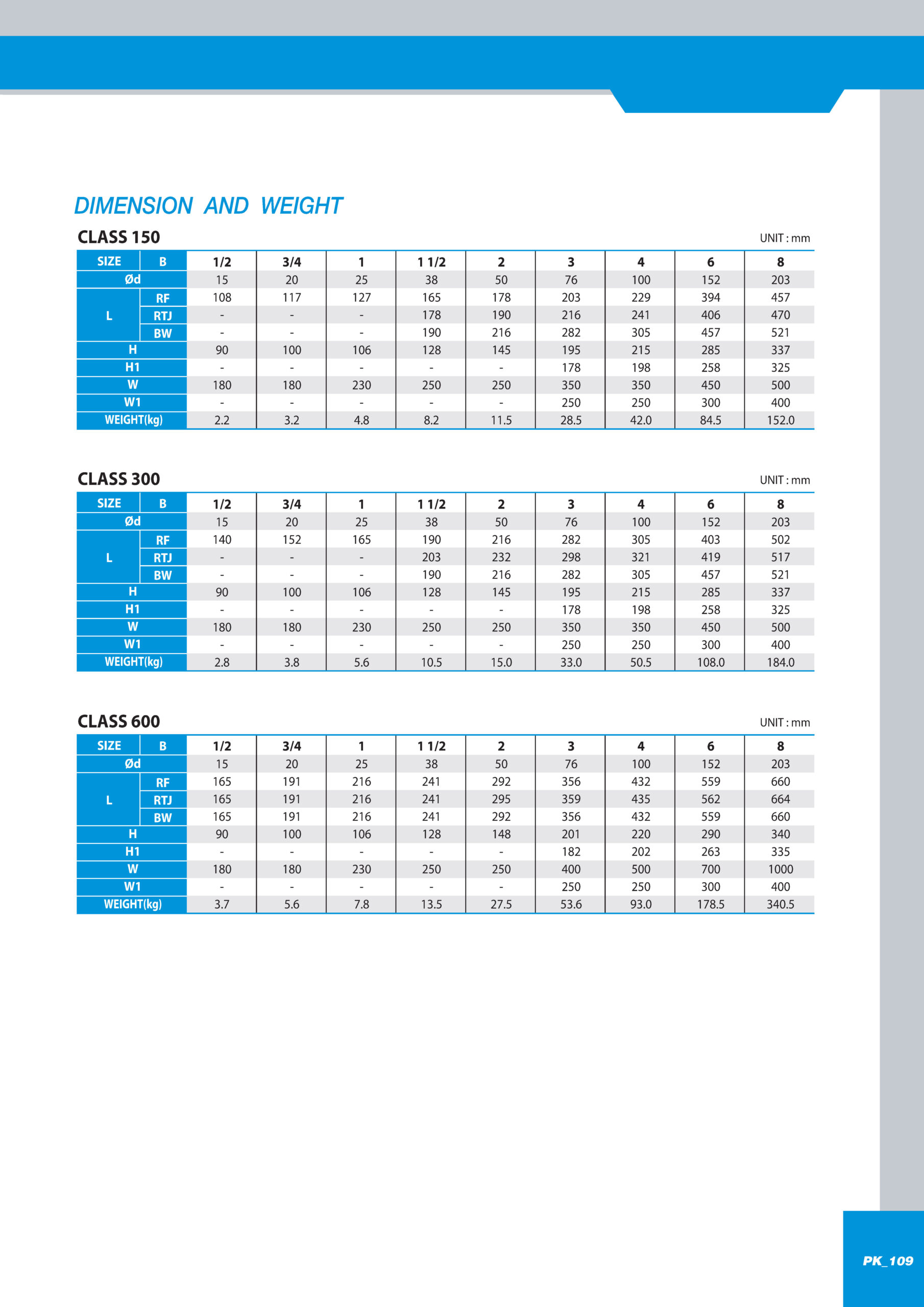

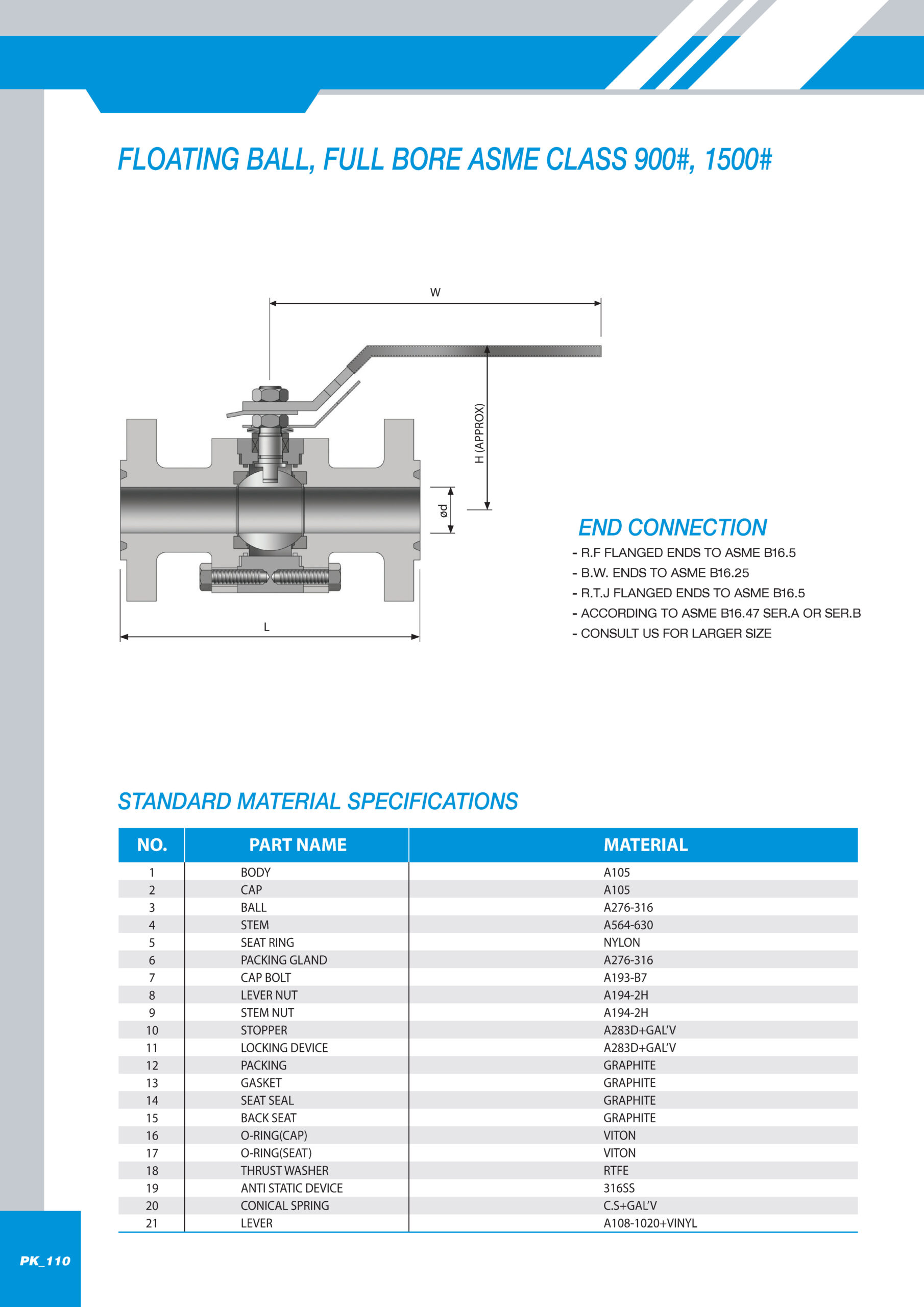

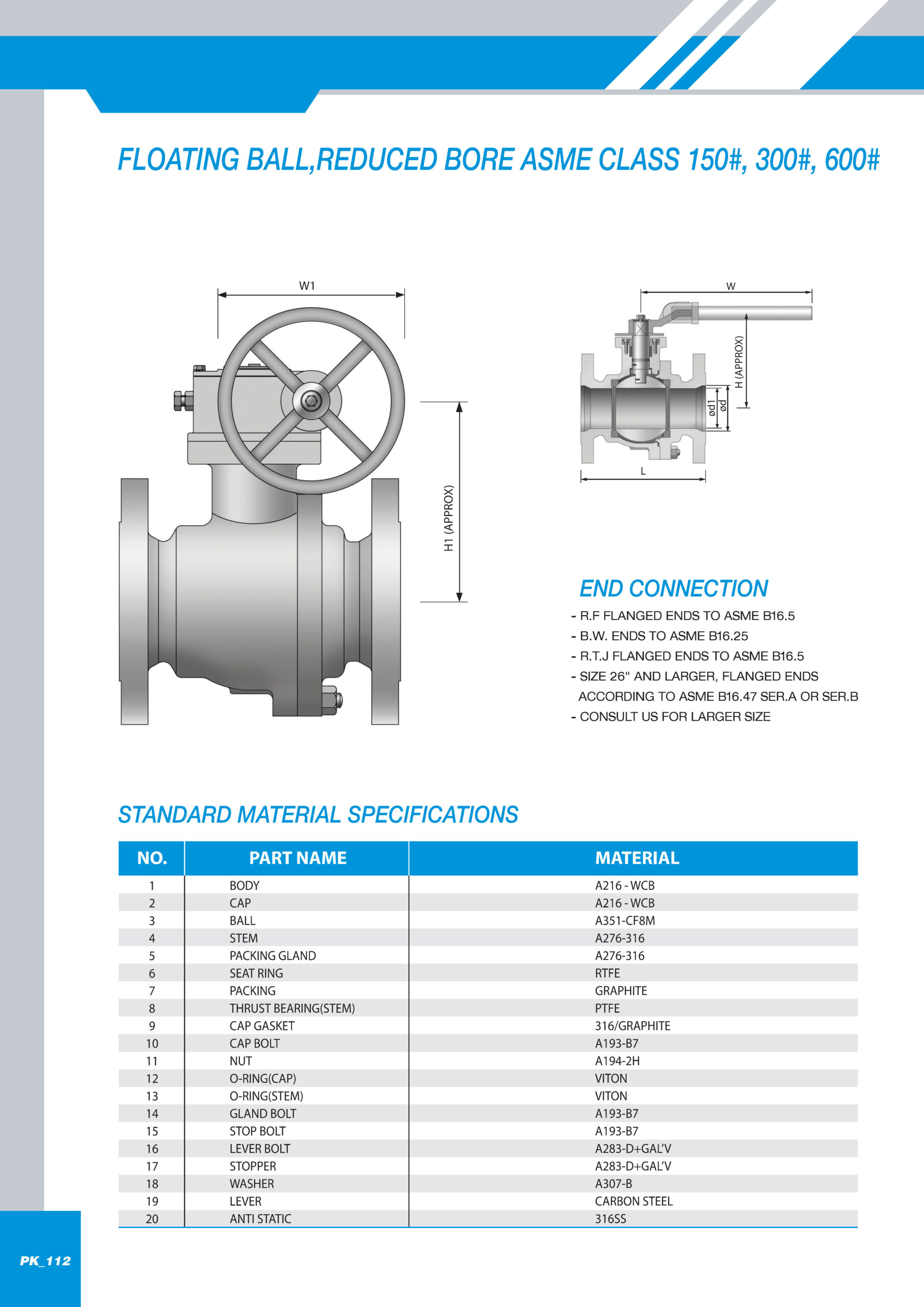

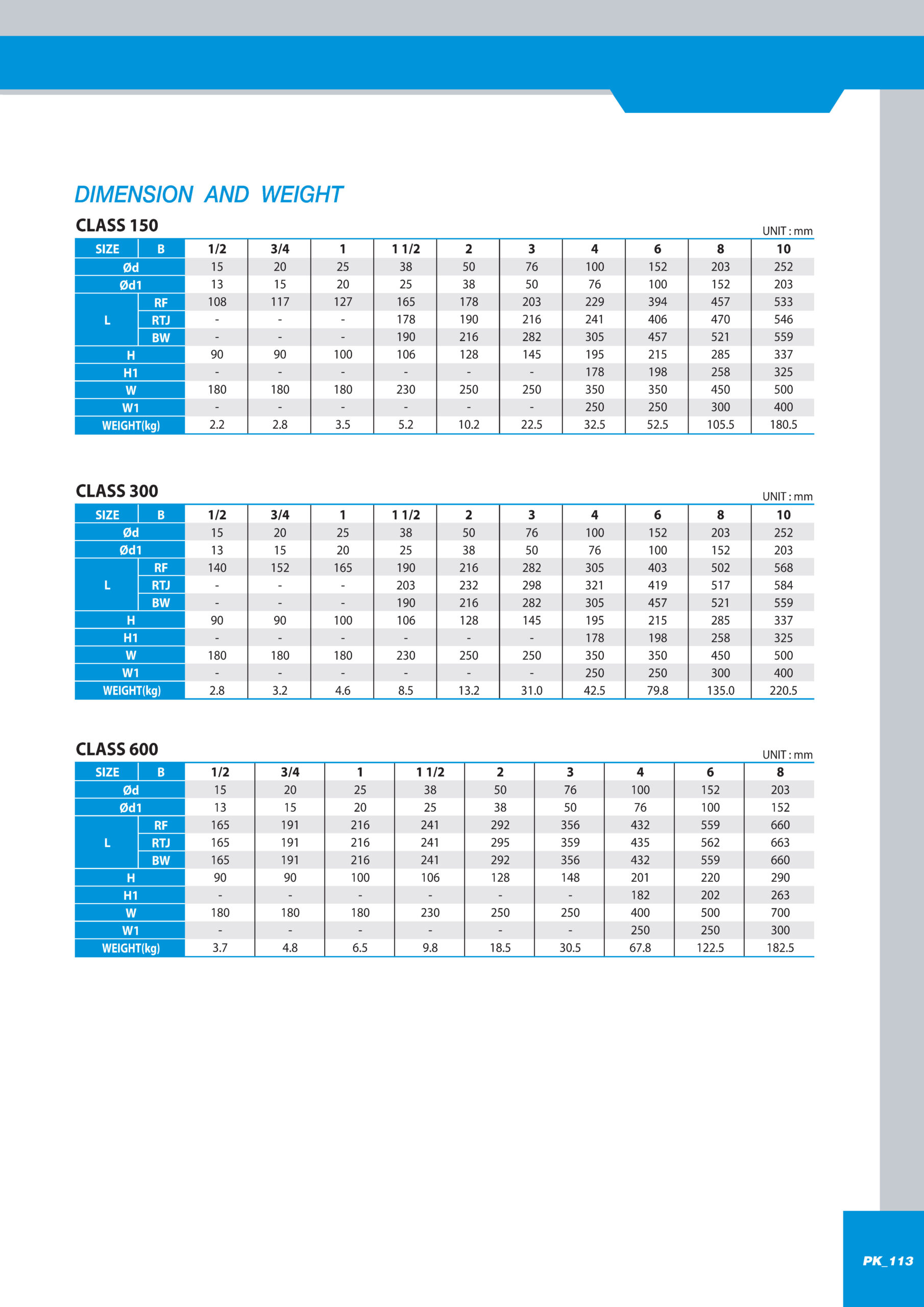

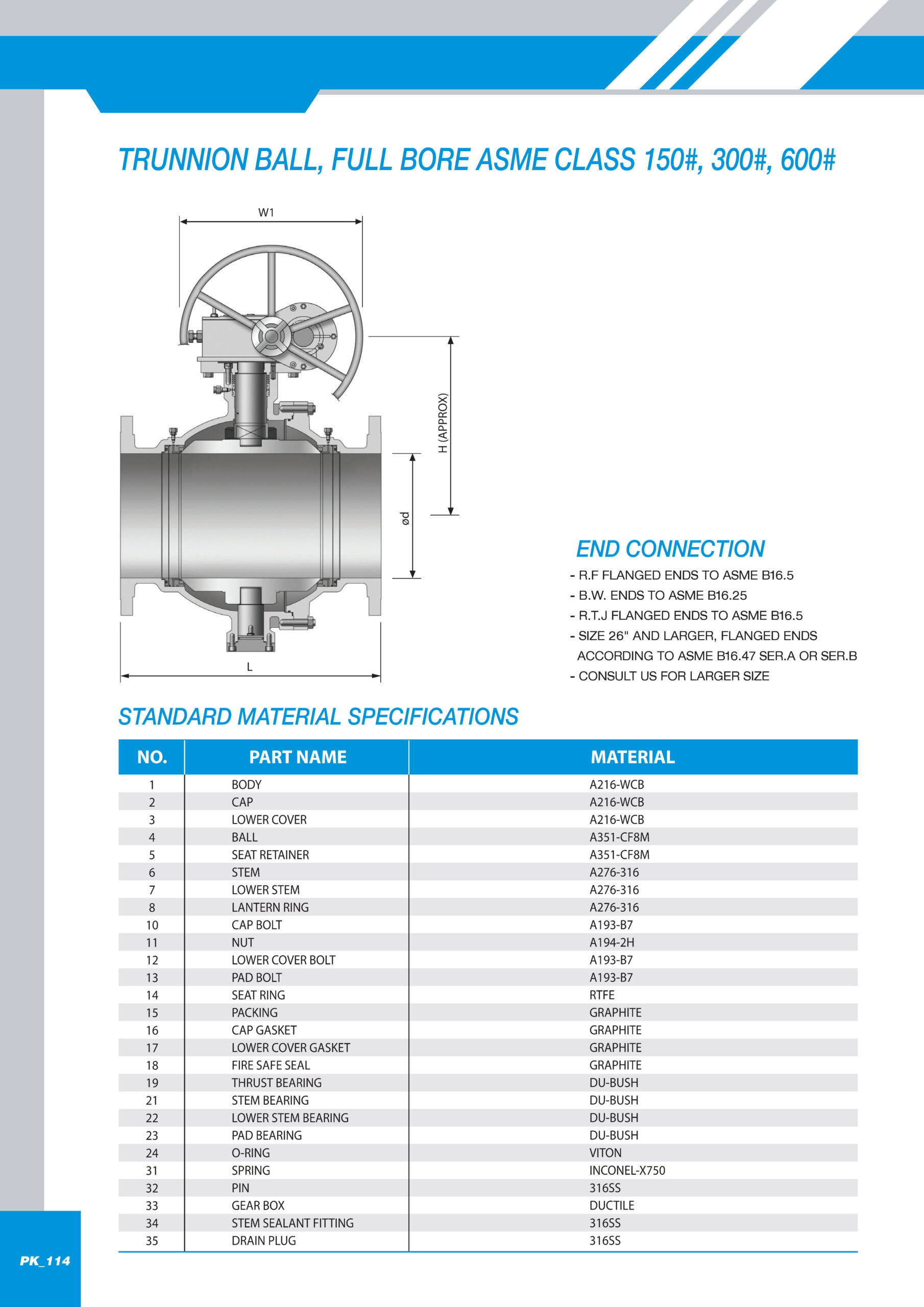

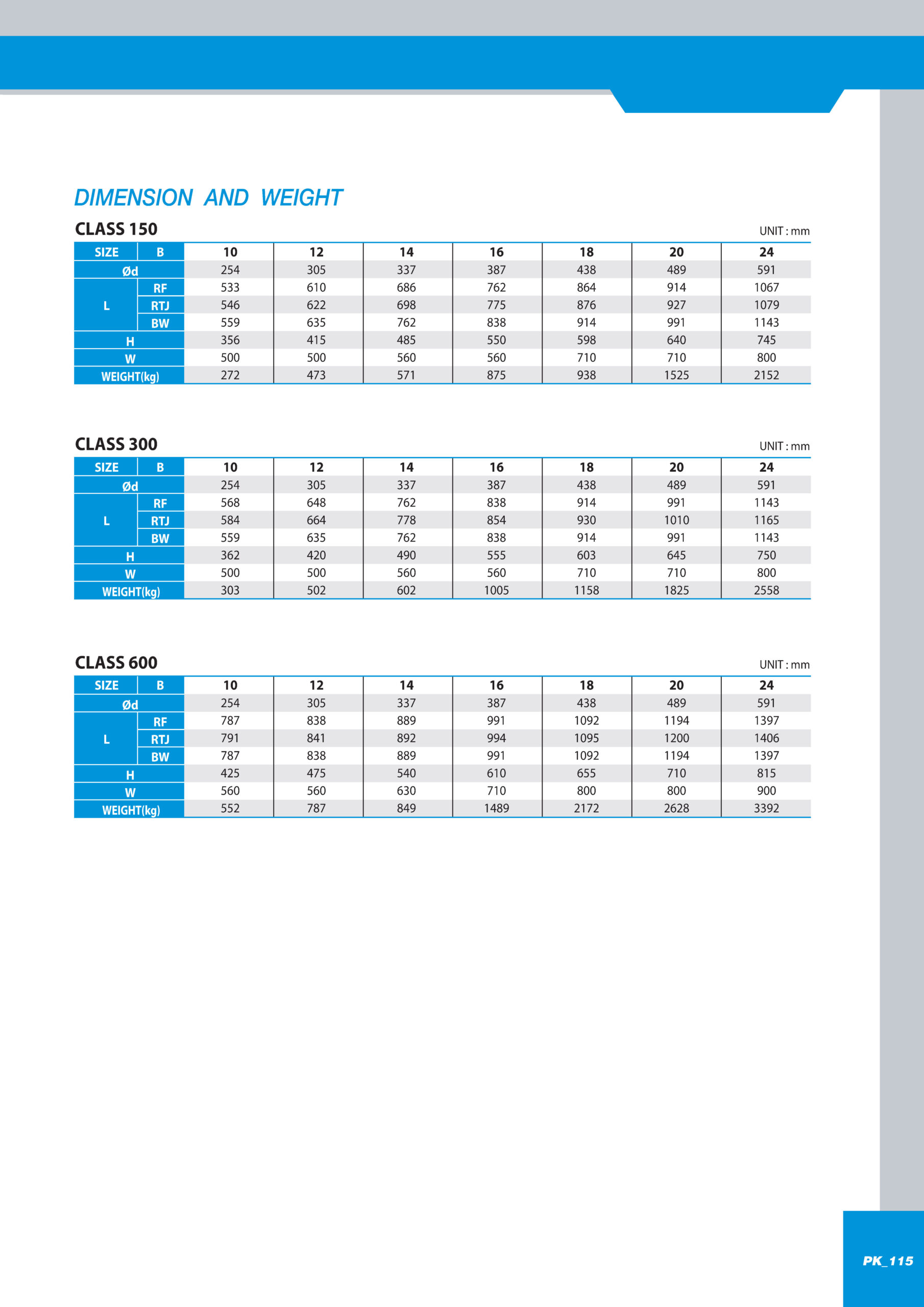

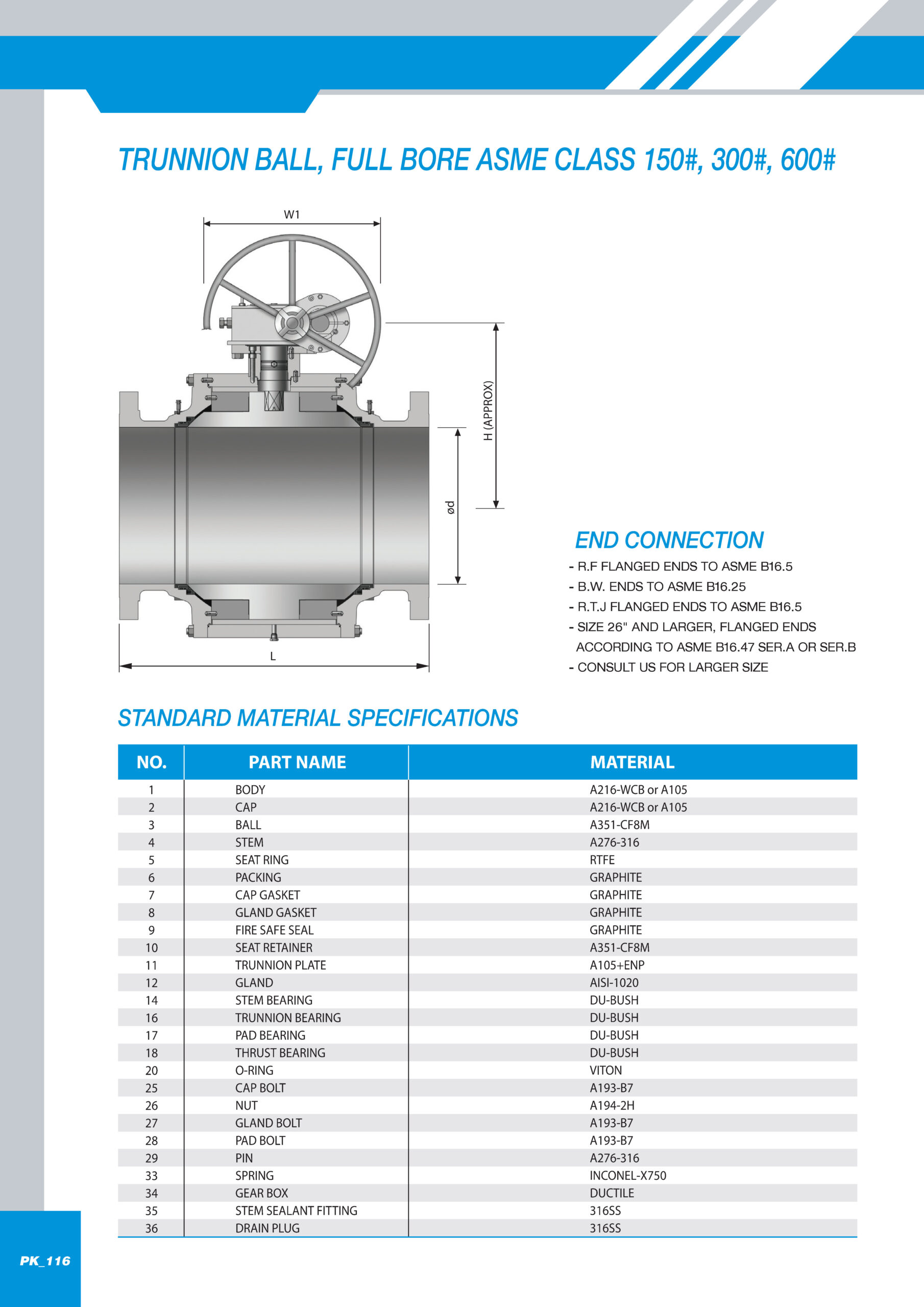

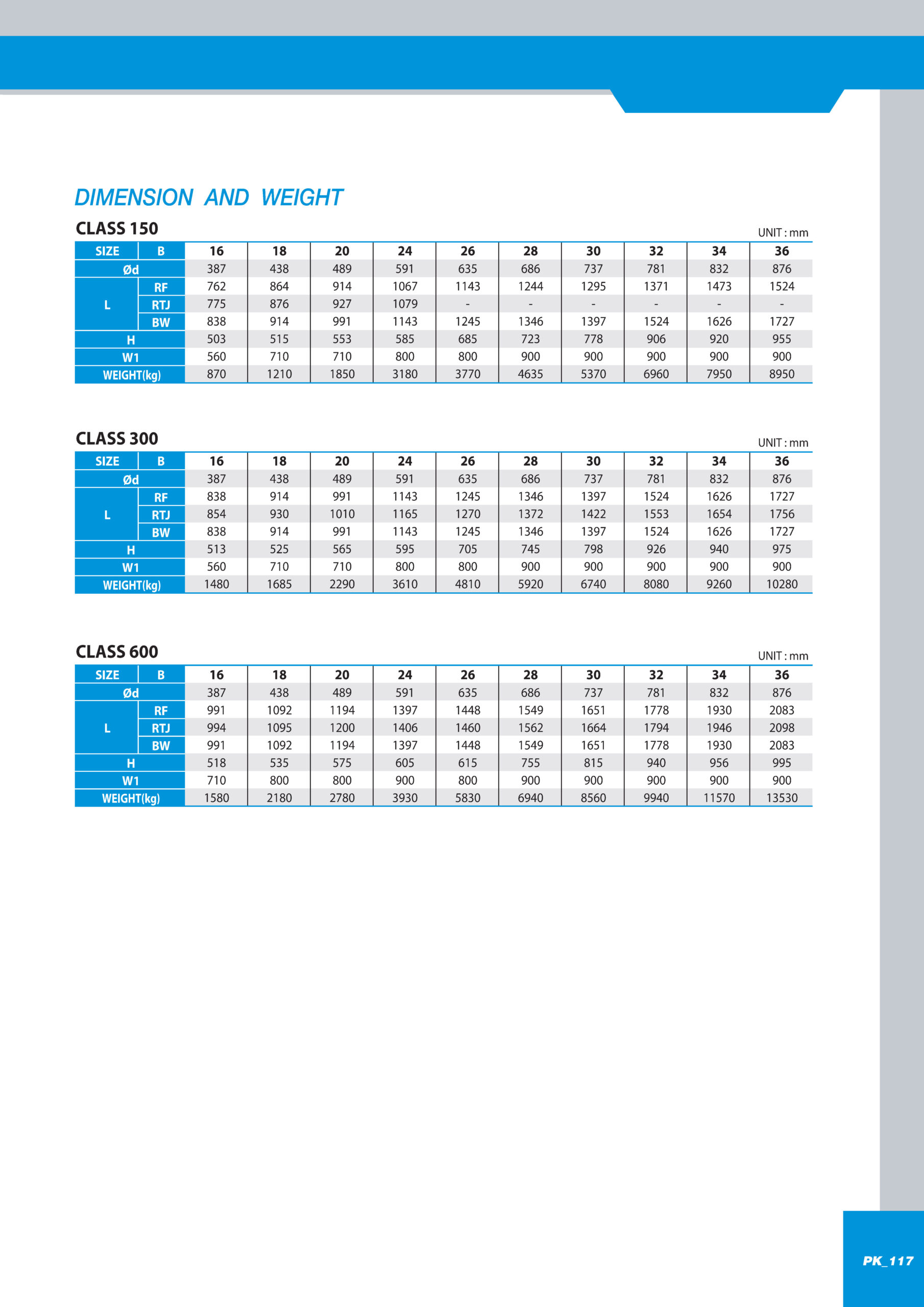

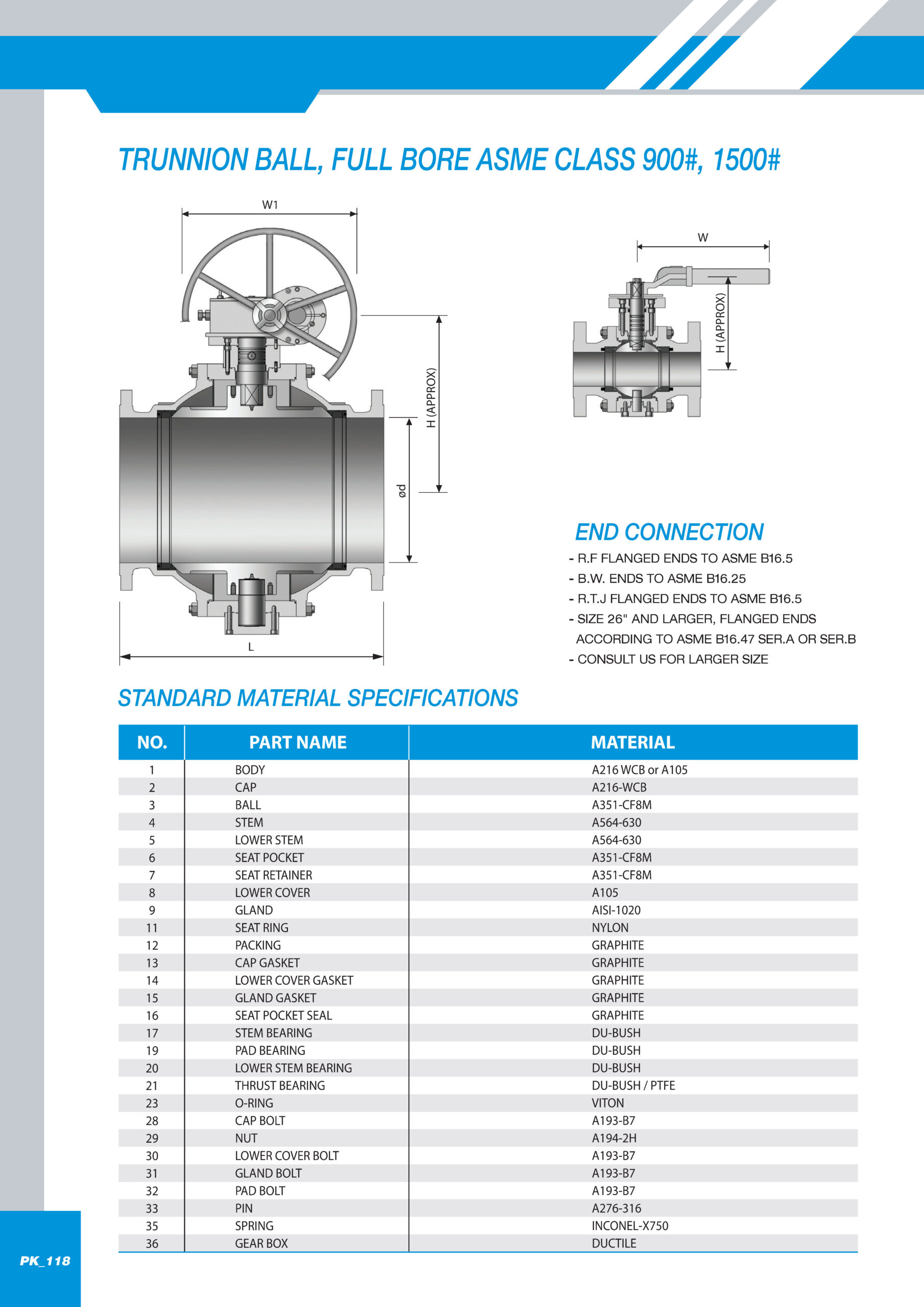

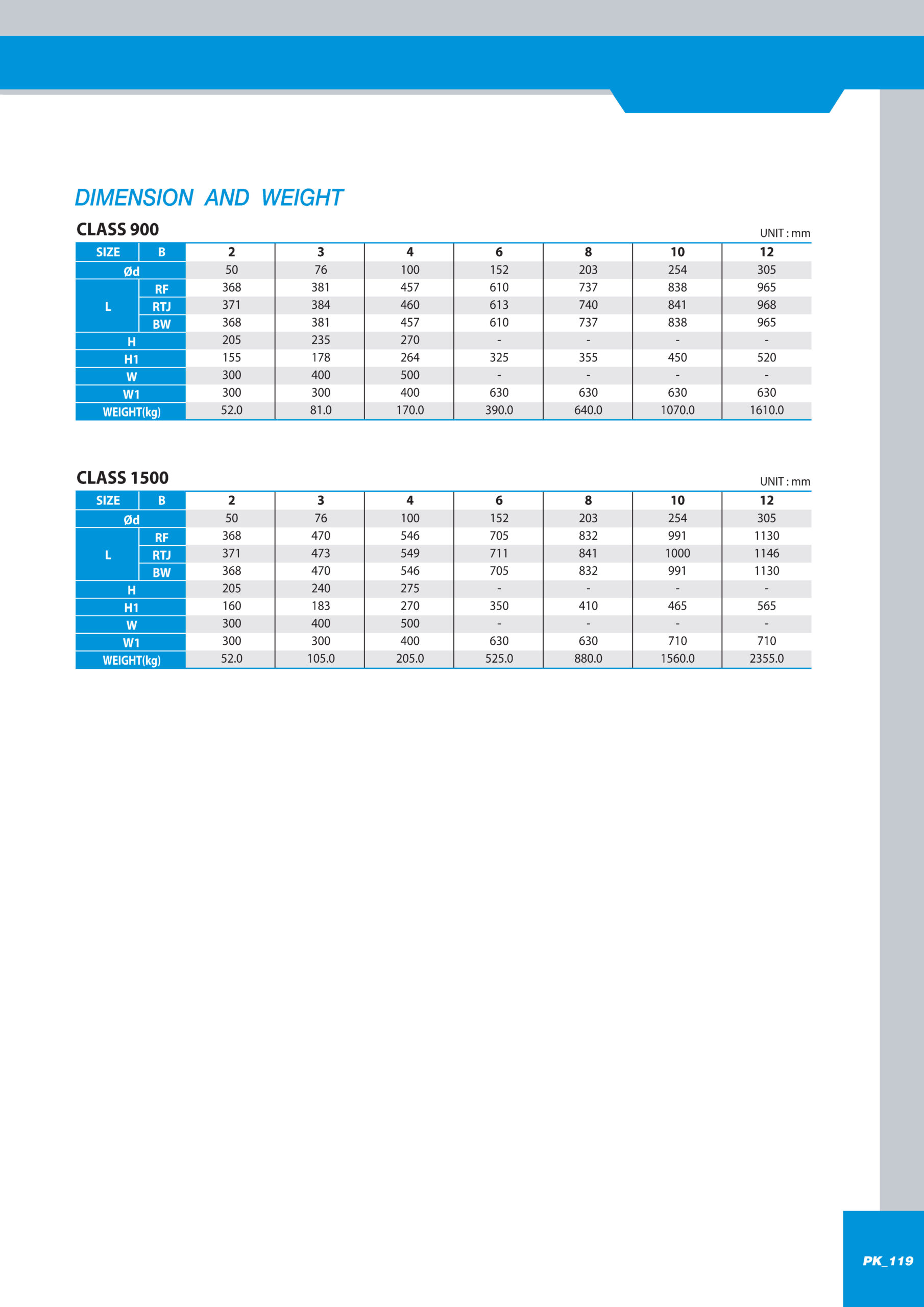

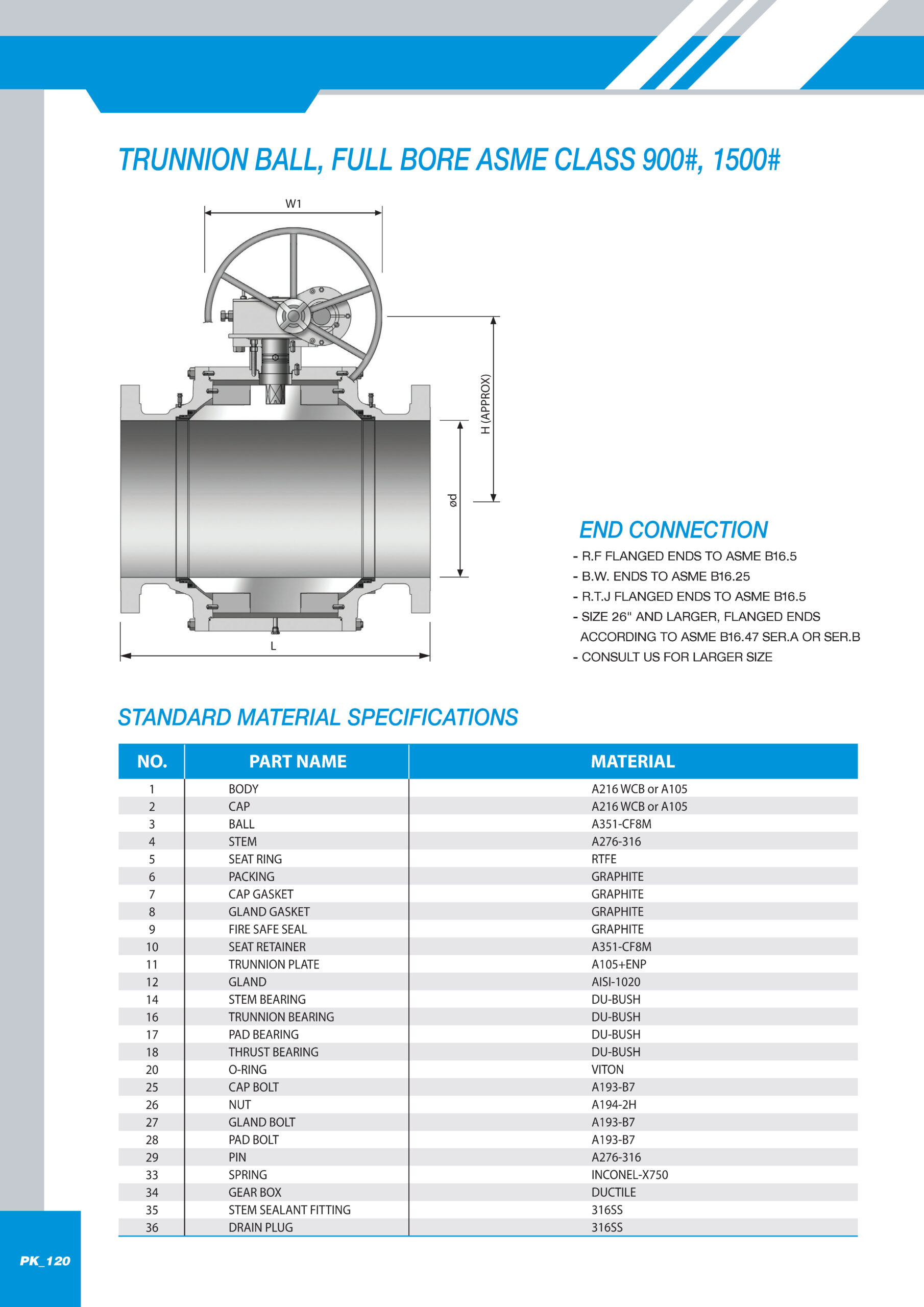

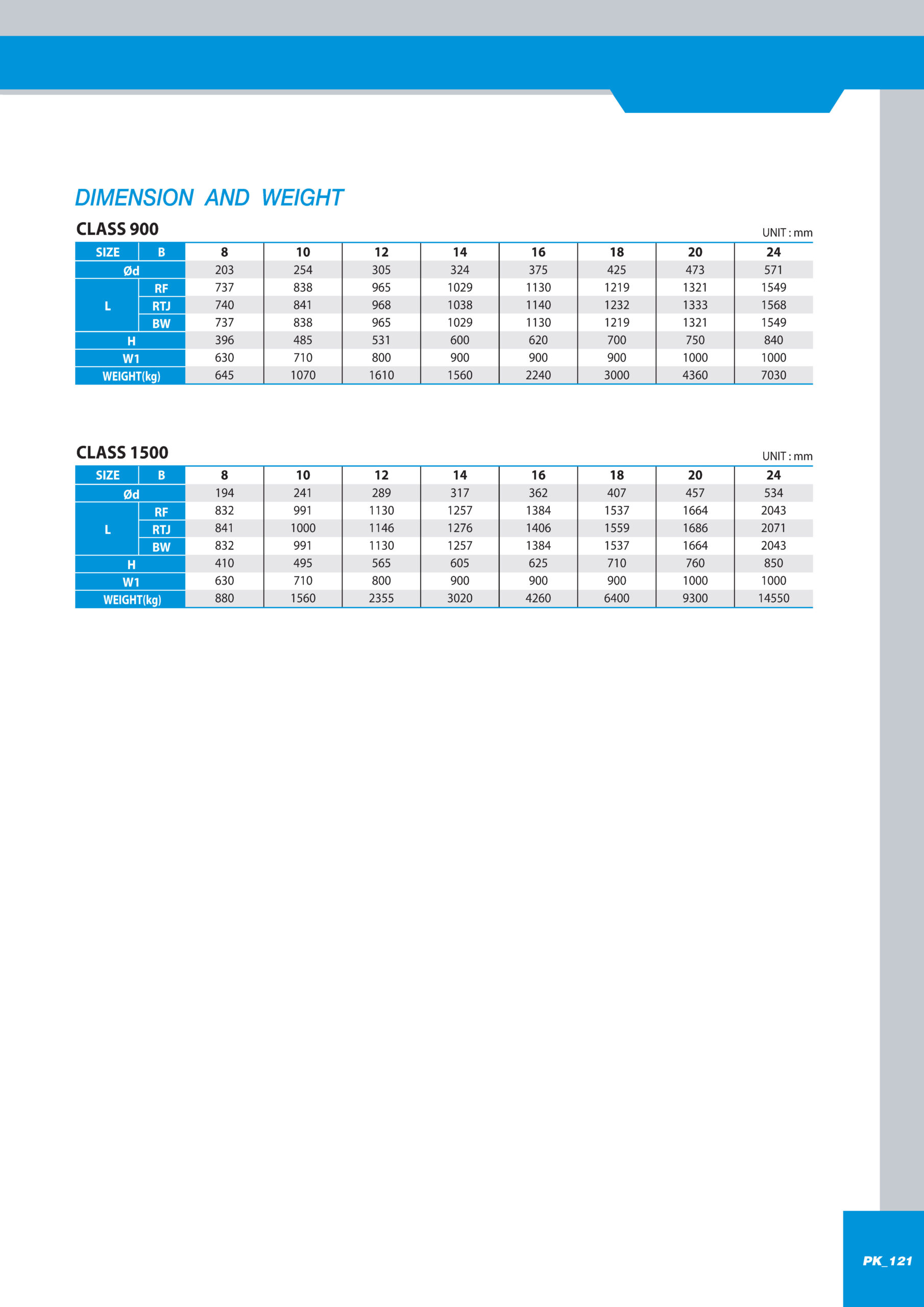

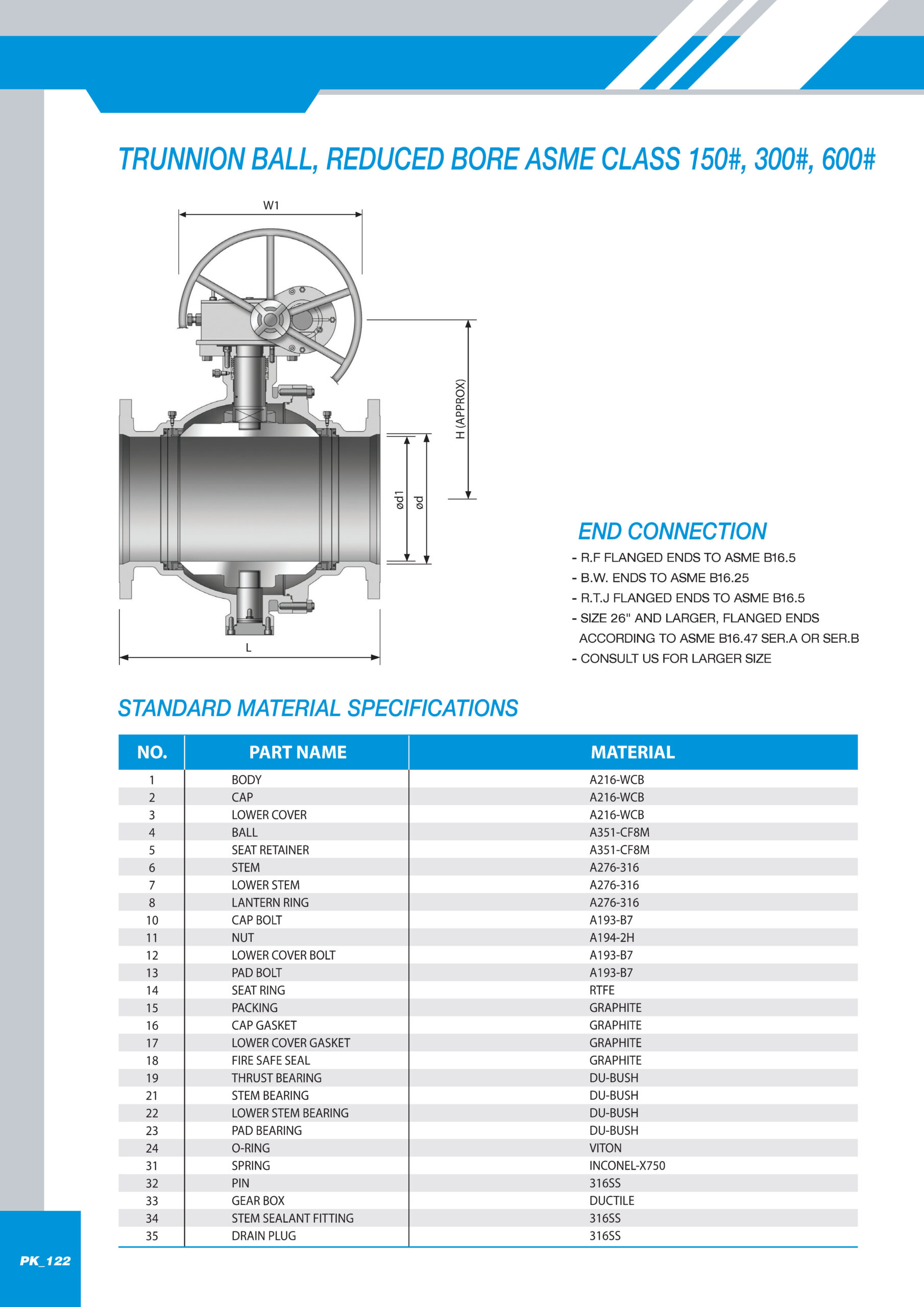

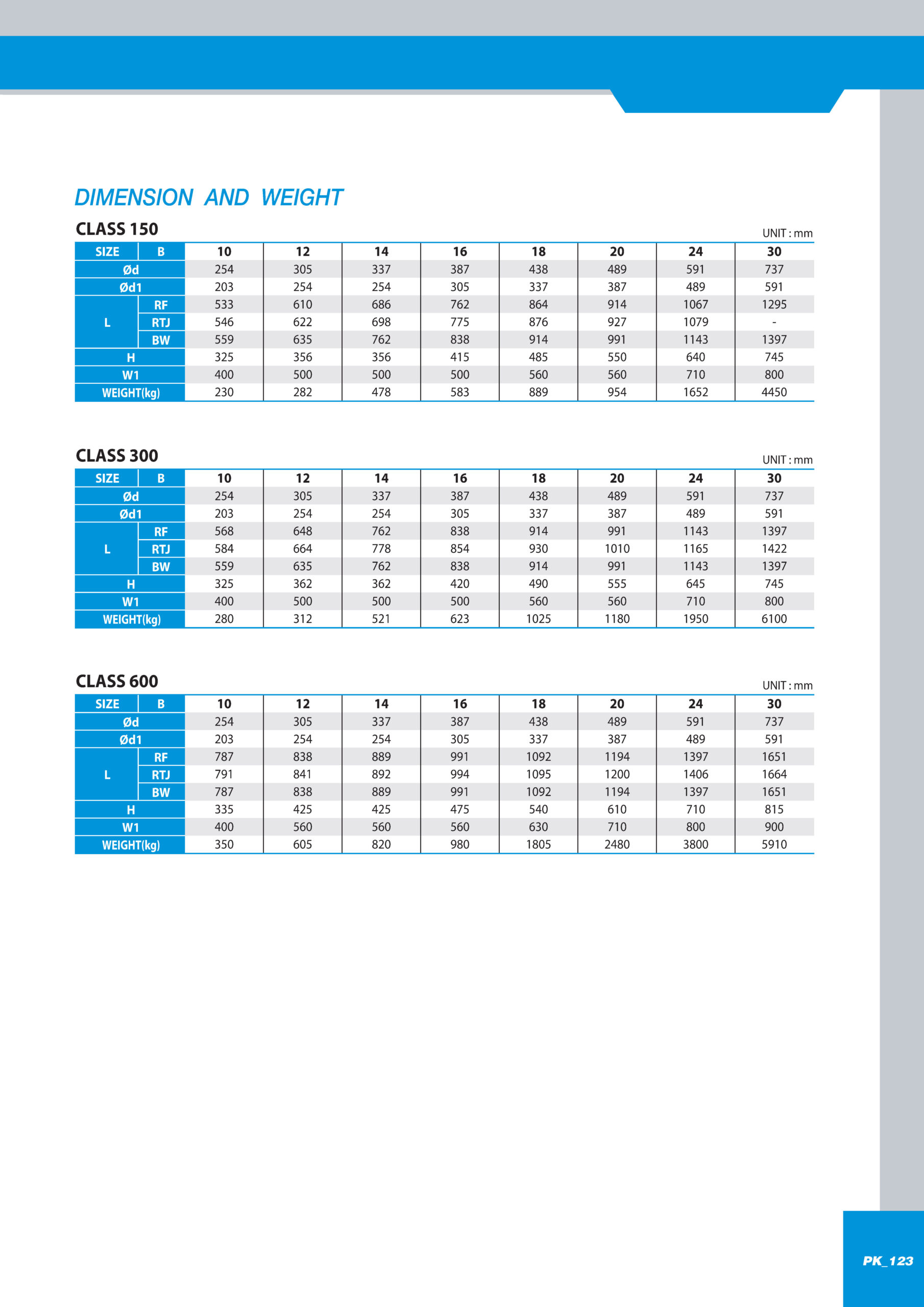

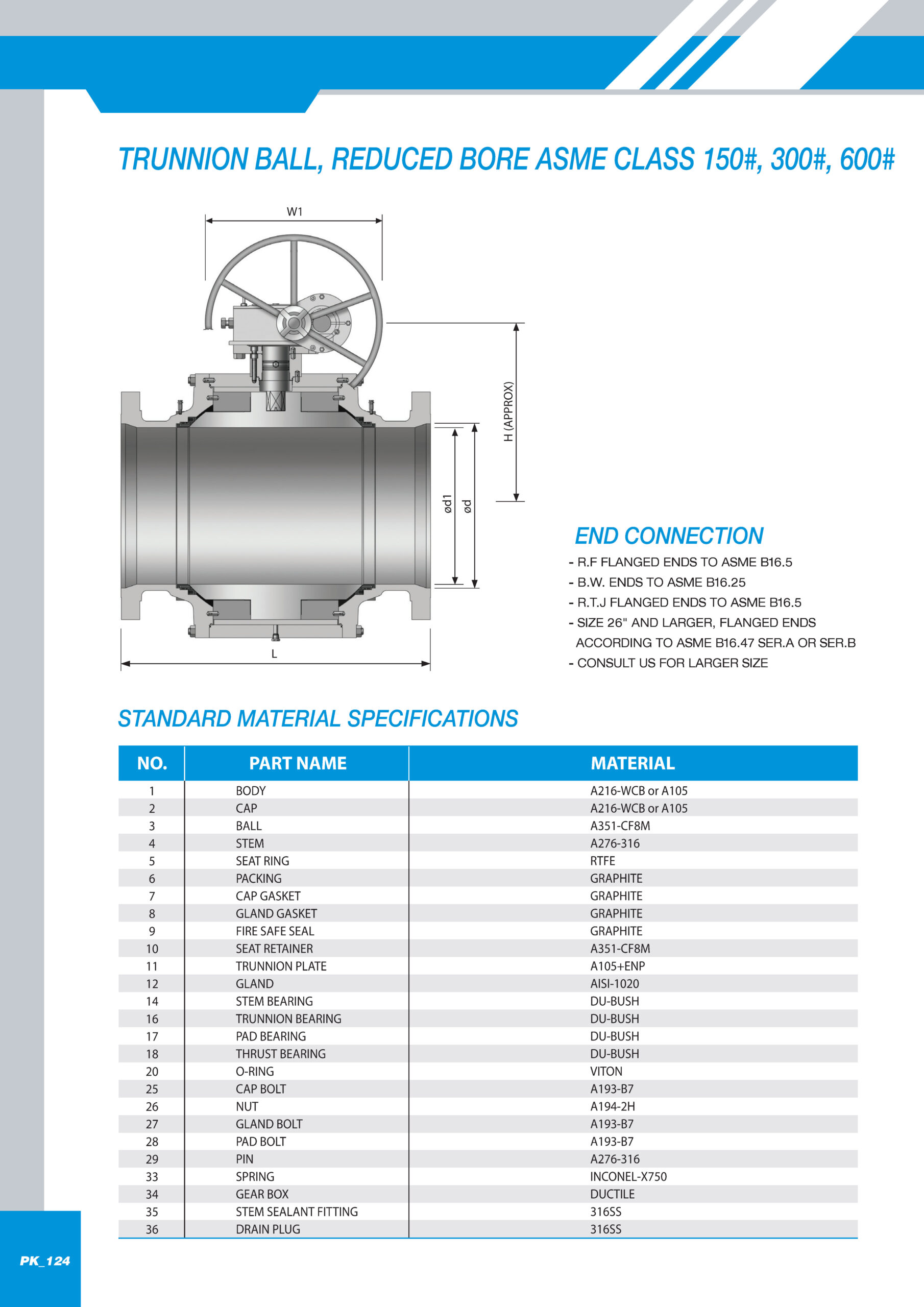

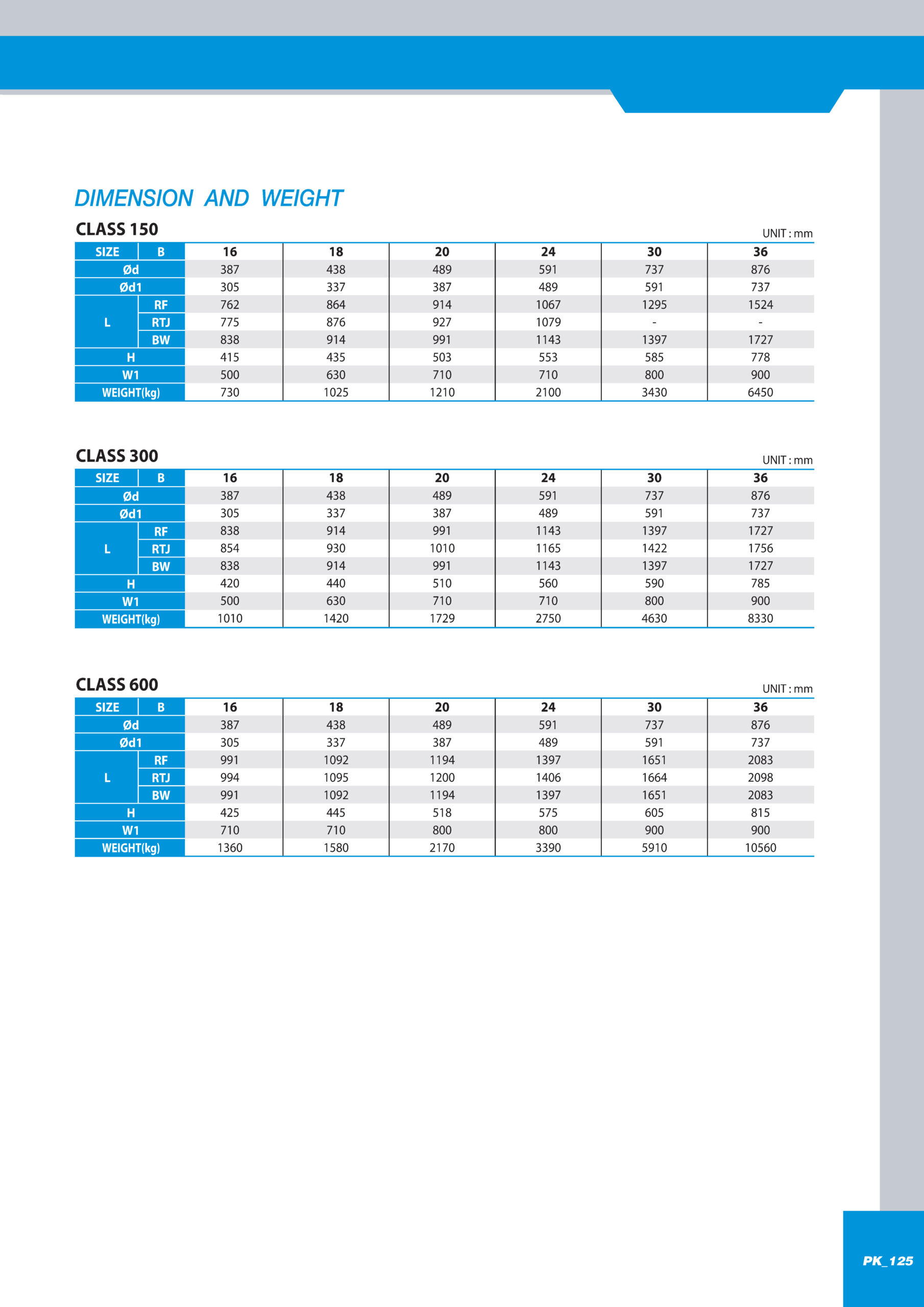

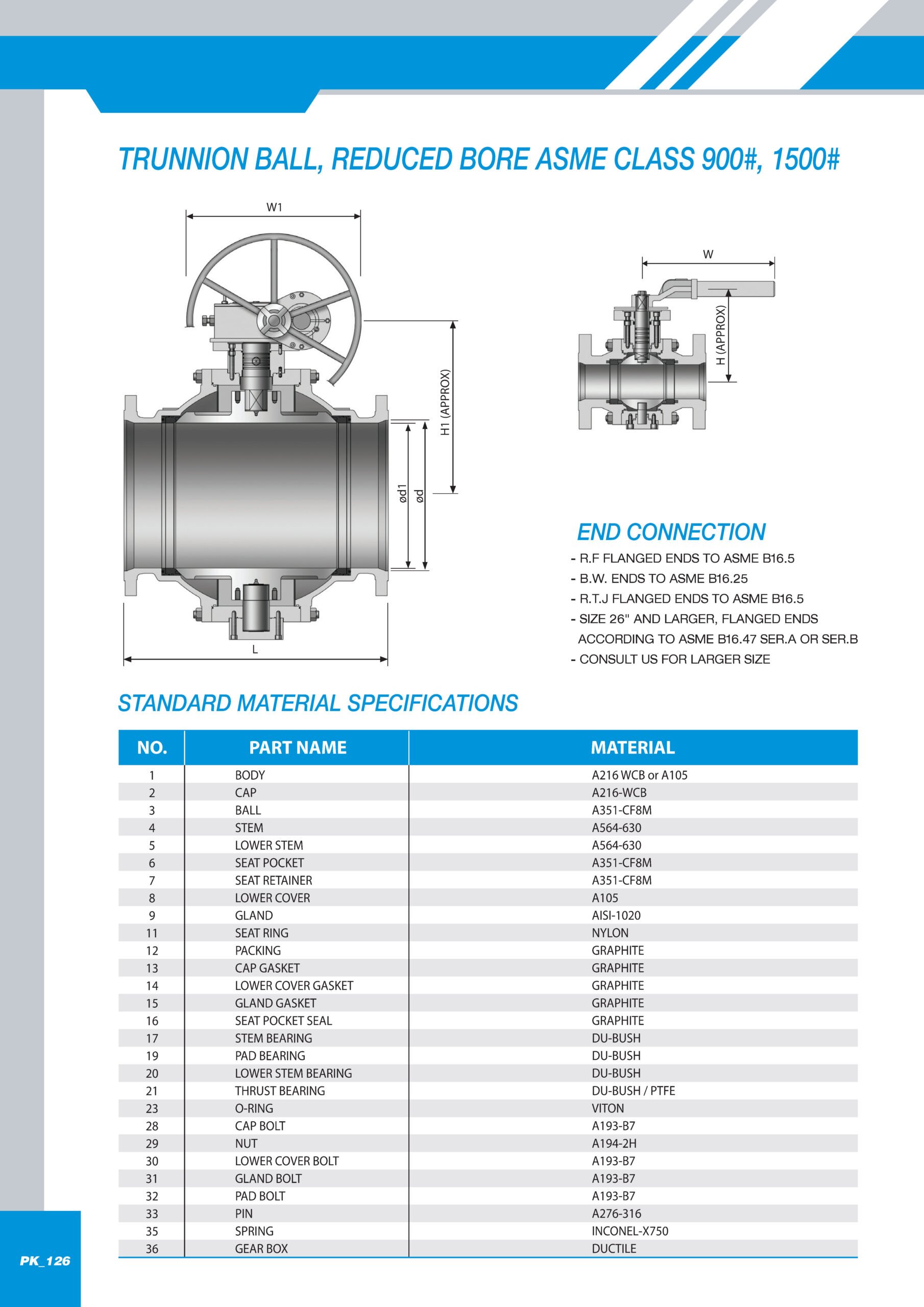

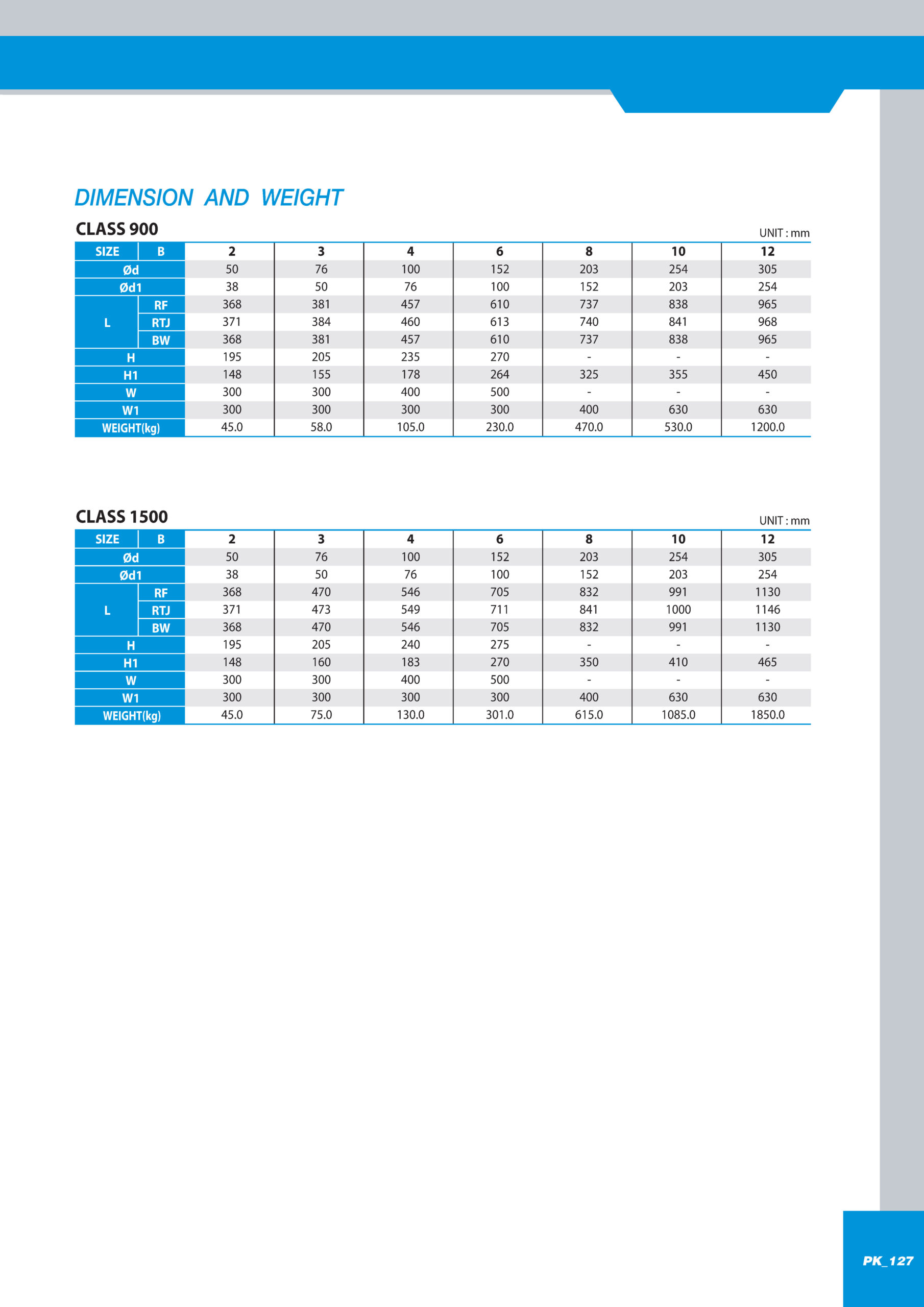

- Size: from 1/2″ to 60″

- Class: 150# to 2500#

- Type: Floating, Trunnion mounted, full bore, reduced bore, Top entry, side entry, DBB, 3 ways …

- Material: Carbon Steel: ASTM A216-WCB or Equivalent; Alloy Steel: ASTM A217-WC6, WC9, C5, C12, C12A, ASTM A182-F91 or Equivalent; Stainless Steel: ASTM A351-CF8, CF8M, CF3, CF3M, CN7M or Equivalent; Duplex Stainless Steel: ASTM A995-1A,2A,4A,5A or Equivalent; Special Alloy Steel: Inconel 625, Incoloy 825, Hastelloy C, Monel; ASME SA designation material (e.g ASME SA217-WC6)

Mô tả

DESIGN AND TEST

Ball valves are designed, constructed, and tested according to API-6D standards.

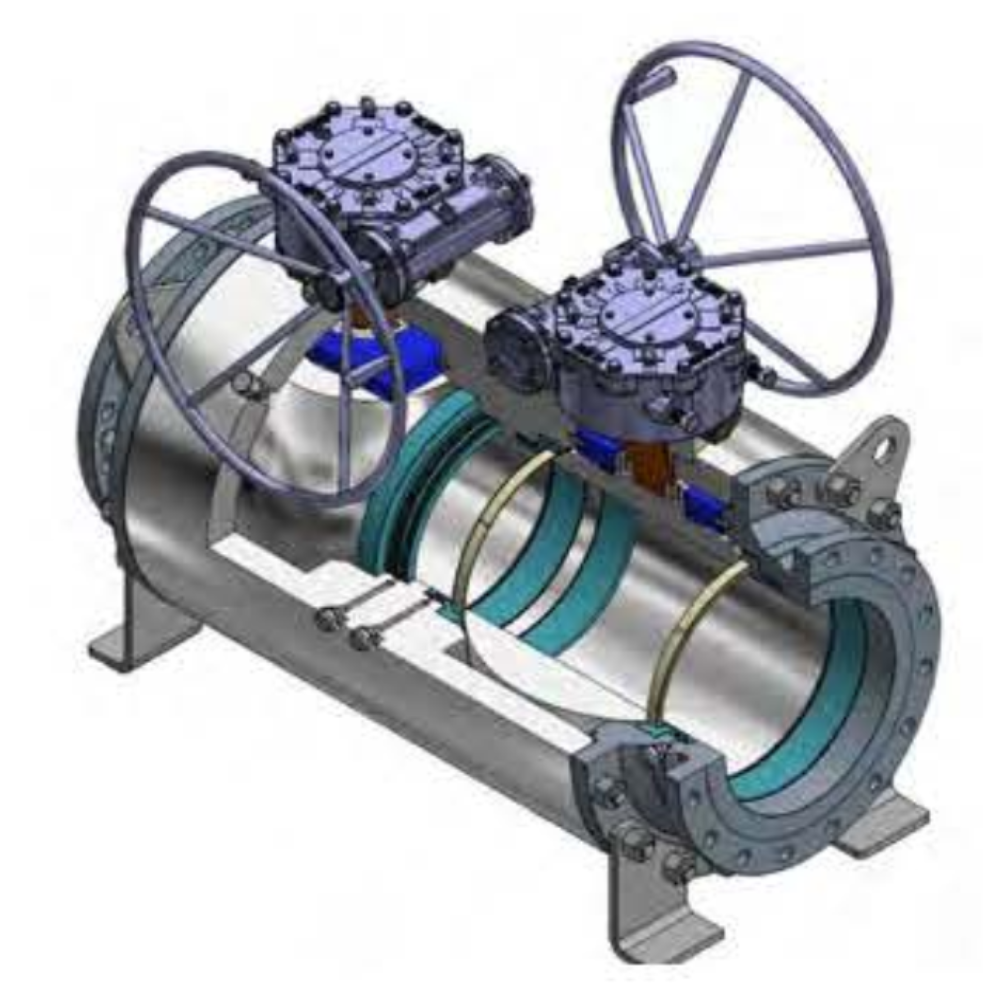

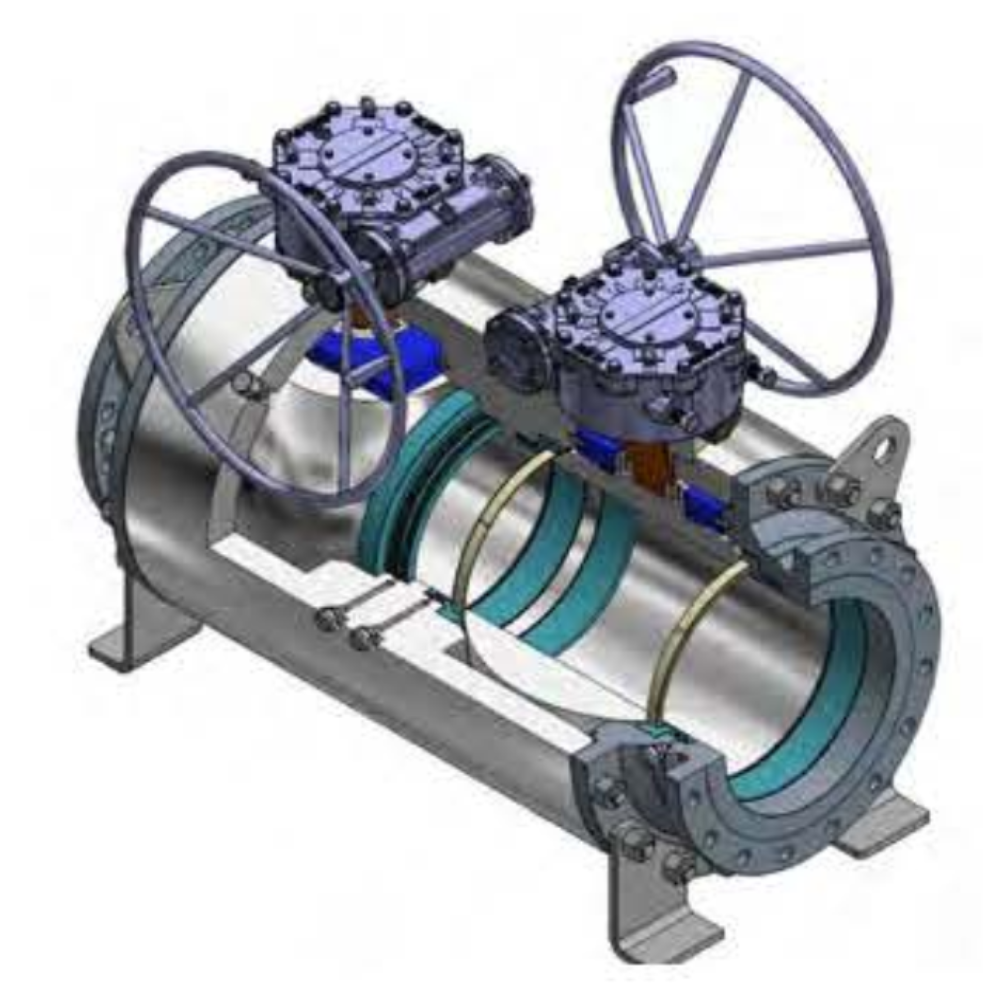

DOUBLE BLOCK AND BLEED

All trunnion-mounted type ball valves employ a sealing principle that facilitates all services required

ring double block and bleed integrity.

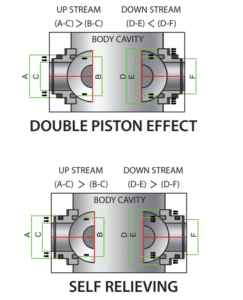

DOUBLE PISTON EFFECT

On request, the seat ring design may be modified to perform the double piston effect action. In this case, the pressure acting on both the external and internal sides of the seat rings, results in force pushing the game against the ball, therefore each seat ring grants the required tightness even if the pressure is applied in the body cavity. This feature adds an extra sealing feature to the valve, but to release the possible overpressure developed into the body cavity it is necessary to use an external safety relief valve.

SEALING PRINCIPLE

All model trunnion-mounted type ball valves are supplied with spring-loaded seats to ensure that the seats are always in contact with the ball. this design provides a very efficient seal even at low line pressure. As the line pressure increases, the seat is forced into tighter contact with the ball providing a positive shut-off.

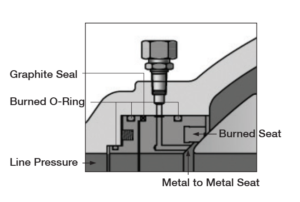

FIRE SAFE CONSTRUCTION

The secondary metal seat is provided to contact between the seat and ball in the event the primary non-metallic seat is destroyed by fire all trunnion-mounted type ball valves are fire-safe designed. The double body and cap seals provide maximum security. It is fitted with special graphite seals to preclude leakage in the event of fire effectively. All top trunnion-mounted ball valves have been tested to API-607 and API-6FA.

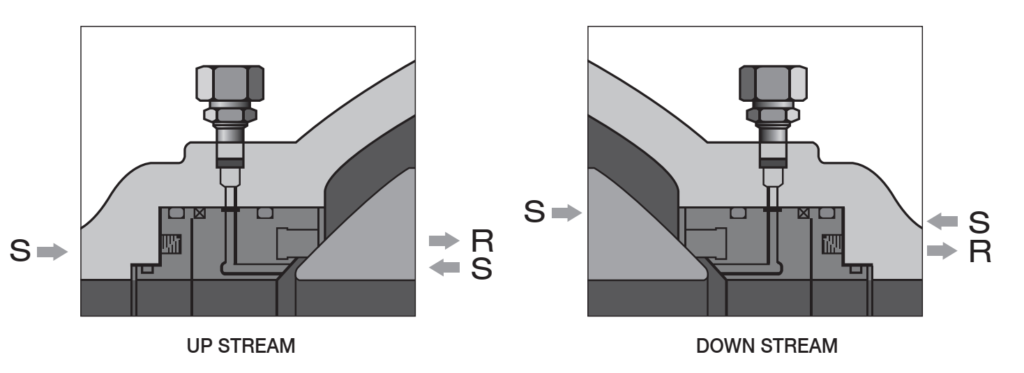

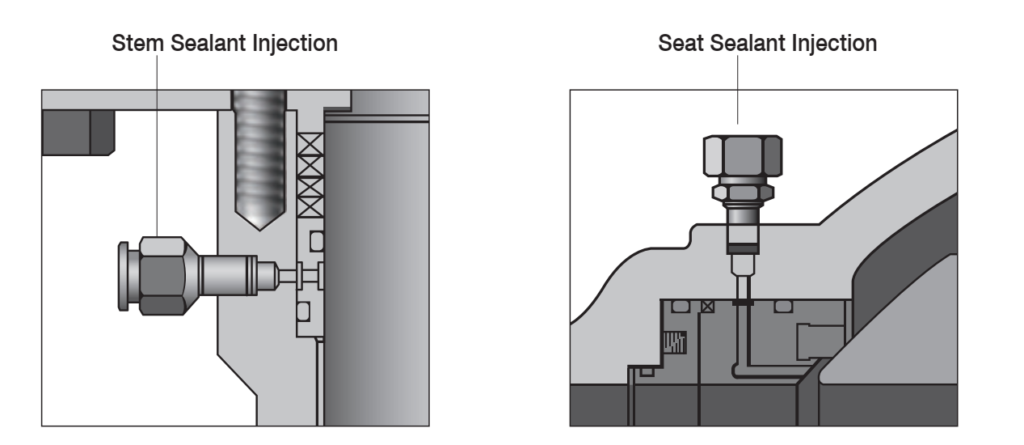

SECONDARY SEAT AND STEM SEALING OPTION

All model trunnion-mounted type ball valves are designed to provide high-integrity shut-off. Upon request, sealant lubrication fittings are installed. In the event of seat insert or stem seal damage, external or internal leakage can occur. Emergency sealant injection can save the integrity of the valve by incorporating a sealant seal around the stem or between the seat and the ball until such time the valve is properly serviced.

AT ALL TIMES-STEM SEAL

This option provides premier valve stem sealing characteristics for adverse conditions of extreme pressure/temperature variations. Designed to meet the most stringent fugitive emission regulations, design is comprised of an extra deep stuffing box/packing/stem seal retainer & conical disc spring. The disc spring provides continuous compression of the packing assembly and compensates for wear.

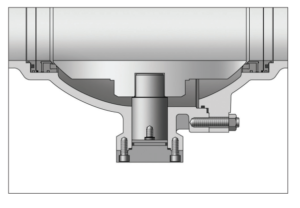

ACTUATOR MOUNTING ISO 5211

All top-flanged end products shall have an integrally cast(ISO)actuator mounting pad. This feature provides for direct mounting of gear operators or electric actuators. The additional cast for separate mounting bracket is eliminated.

STATIC SEALED STEM SEAL RETAINER

The stem seal retainer, with its (2) static viton o-ring seals; Accepts the forces provided by the combination iso mounting pad/packing gland & transmits those forces as packing/disc spring factory pre-load. A variety of o-ring seals are available for those exceptionally demanding applications. Field maintenance & costly repairs are virtually eliminated.

SPRING FORCE

Optional conical disc springs ensure adequate loading of packing at all times. Excessive stem torque and packing deformation due to over-tightening of conventional packing glands is eliminated. The constant “LOAD” provided by the disc springs compensates for normal wear-repair and maintenance costs are virtually eliminated.

PACKING

The high-pressure/ high-temperature packing set is comprised of self-cleaning, die-formed, high-density, and low-density graphite molded packing materials. This unique design eliminates stem galling, lowers required valve stem torque, and increases product performance.

ANTI-STATIC DESIGN

Ball valves present a particular problem with the build-up of static electricity around the ball. They have anti-static design which provides contact between stem and ball, and stem and body to eliminate static electricity.

TRUNNION LOW STEM DESIGN

Trunnion mount design locates the low stem trunnion assembly within the confines of the body & cap. In so doing, both the line pressure and media act upon all valve cavity components equally.

The advantages of such a design include:

- The pressure & media do not concentrate in one location only, instead, the forces are dispersed equally throughout the pressurized areas.

- Ball movement and side loading of lower stem are minimized, thereby decreasing operational torque valve and improving stem seal life end.

- Guarantee the low torque and extend valve life.

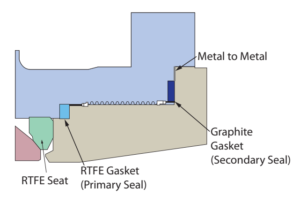

UNIQUE DOUBLE SEALING DESIGN AND METAL-TO-METAL CONTACT

UNIQUE DOUBLE SEALING DESIGN AND METAL-TO-METAL CONTACT

The PTFE gasket acts as the primary seal for top unibody ball valve. the secondary seal is made of flexible graphite; A material with extremely good resistance to fire conditions

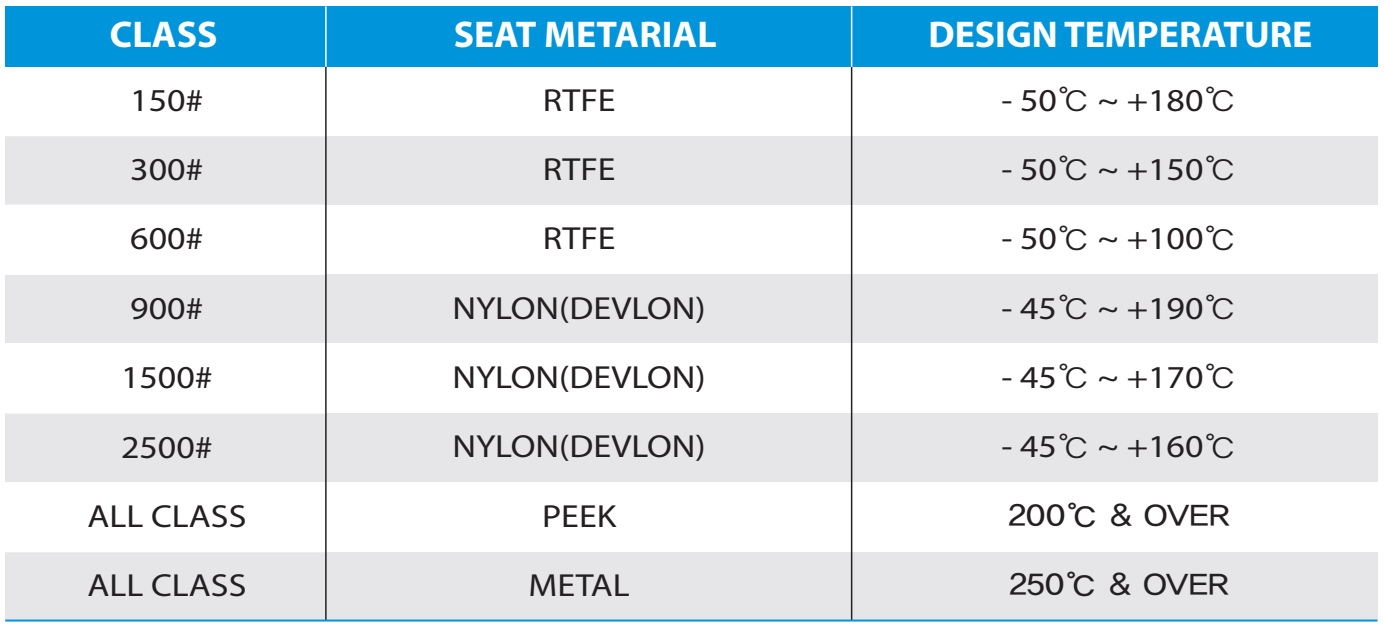

APPLICATION OF SEAT PER TEMPERATURE

Đánh giá

Chưa có đánh giá nào.